For our final Assessment in Science this year, we were challenged to build a building to withstand an earthquake made out of spaghetti and blue-tac. It was a tough challenge for many reasons, but we worked well and collaborated to build a building that exceeded most criteria. I was in a group of 3 with Sascha and Amelia.

Why build an earthquake-resistant building?

Many places world-wide suffer from horrible earthquakes which break down buildings and leave thousands injured or dead every year. For many places, any buildings that are damaged or destroyed are inhospitable for months or even years. In 2015 an earthquake struck Nepal and left the city with devastating consequences. Many were left homeless and the falling buildings killed many. In 2017, less than 5% of the destroyed houses had been rebuilt, meaning over 800,000 families were still left to live in shelters.

Our building is easy to assemble, cost-friendly and withstands these earthquakes, being made from lighter materials means that in the case of an earthquake, any falling rubble won’t injure people as much.

Design Brief

We were challenged to design a building that would withstand a major earthquake. We needed to design, build and test a small-scale model that meets the following building success criteria:

- is quick and easy to assemble

- has a minimum height of 60 cm

- has a maximum base of 30 cm x 30 cm

- has a flat platform on the top level of at least 5 cm x 5 cm (this will be supplied to you)

- remains standing after an earthquake, as simulated by shaking a table for 10 seconds

- is constructed from the materials provided by your teacher

- costs less than $60 to build,

- one stick of spaghetti costs $1 and is around 25 cm long, 1 gram of blue-tac costs $1

- This budget will be provided twice: once for the initial prototype, and once again for the second prototype.

50-Minute Design Sprint

In our 50-minute design sprint, we challenge to design an earthquake building that will resist the energy passed through it by P-Waves & S-Waves. In the design sprint, we used $50 of the money to create our model.

We had no time to research anything, and no designs to base our model on so we just started building. It was over the height requirements and was holding, then in the last 3 minutes the main piece of spaghetti broke and the entire building collapsed. by the time we got to the shake table our pile of spaghetti was 2cm tall. it didn’t fall when it was hit with p-waves, s-waves or surface waves, but we did not pass.

Improving & Re-Designing

After the design sprint, we had to re-design our ideas. We all decided right away that we would not rely on the 1 main structural support to hold it up as this failed us in the 50-minute design sprint. We decided that it would be better to have a smaller surface area for the building. This would give us more spaghetti to build the rest of the building with, therefore it could be taller and we could make the building more strong by doubling some pieces of spaghetti.

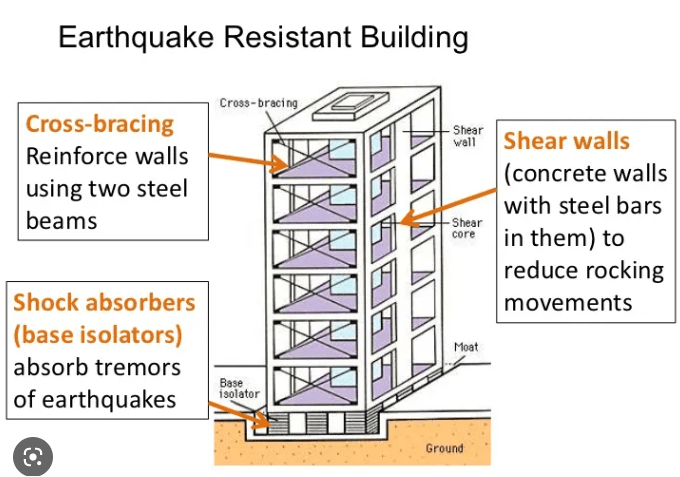

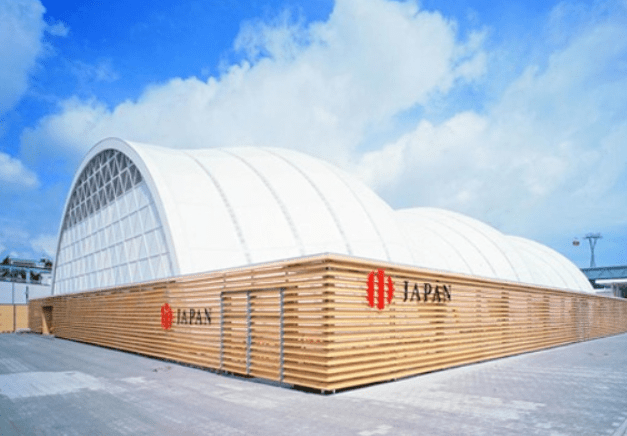

We also looked into designs around the world for earthquake-resistant buildings. In San Fransisco, there is a skyscraper called TransAmerica. It is 48 floors high and every floor is slightly smaller than the one below. The top floor is too small for anyone to stand on, this is because it’s a pyramid shape. Pyramids are one of the strongest structures as they are sturdy and have got structural support. In Japan, there is a building made entirely out of paper. This is so if it falls in an earthquake, fewer people are injured by falling pieces of rubble.

Our Final Design

In our final design, we used features from all the buildings. We like the cross shapes on the paper building in Japan, and we thought this gave the building extra support, so we used it for the walls. We used the TransAmerican Building’s idea and made it get slightly smaller as the building got taller. We halved the base size of our design from the 50-Minute sprint in our final design.

Building & Testing

When we were ready we decided to start building. We didn’t end up doubling our pieces of spaghetti, as we had originally planned, this was due to not having enough extra spaghetti and because we made a new plan to only double the pieces that weren’t as strong or looked like they would snap. We used all our money in one go. We knew it was risky we knew it would pay off and we couldn’t create our final build without using it all. We split our $60 in a 40/20 split. $40 of our money went to spaghetti and $20 went to blue tac. We took our time and made a rule that only 1 person could add/remove/change a piece of spaghetti at a time. This meant that we all knew what was happening throughout the entire building process. We finished the building process at 30 minutes and 50 seconds and did our first test.

Results

To our surprise, our building held up through all the different types of waves and was even able to be flipped upside down without falling.

Conclusion & Changes We Would Make

Overall we were very happy with the outcome of our building. It held up through P-Wave, S-Wave and Surface Wave Simulations, and it could be flipped upside down. We all agree that our group worked well together and by listening to each other’s ideas we were able to create a better building that could stay up and not fall like the one in the 50-minute sprint.

If we did it again we would focus more on the building in the 50-minute design sprint, this way we can use the design sprint as a model and create small changes in our real one instead of having to redesign the whole piece.

We also discussed changing the surface area. If we made it bigger it could cater to more people and we could see how big we could get it before it fell apart again, or we discussed making the surface area smaller. This way it could still be big enough to hold the 5 by 5 platform on top but the smaller surface area would mean we had more blue-tac to hold it together and it could be taller. Even though some of us had opposite views, this could be tested next time to work out which design would work best.

Overall we were pretty impressed with the outcome of our building as we did not expect that it would hold as well as it did.