In science for a final assessment, we were given an engineering task. We split into groups of 3 and were challenged to design and build a small building for under “$60” out of spaghetti and bluetack – where spaghetti was $1 for 10cm and bluetack was $1 a gram. It must be maximum 30cmx30cm base and minimum 60cm high. It then must survive 10 seconds of simulated earthquakes.

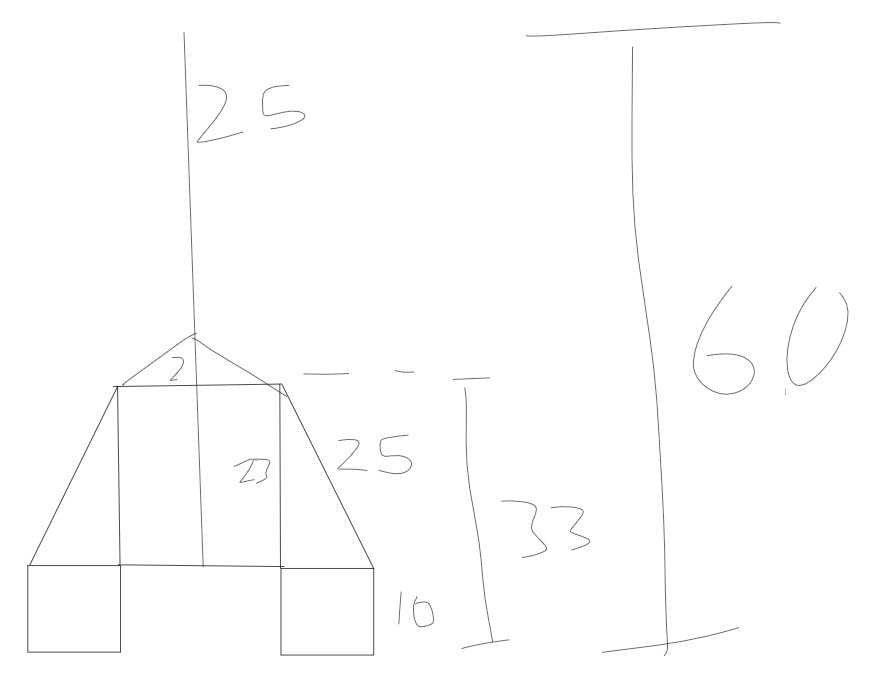

We have used triangles to gain max strength as they are a well-known structural shape. My hypothesis is that because it is made of triangles it will be able to withstand force from all directions and remain standing. Because it is triangles we don’t have to spend as much money as if it was squares because it uses half as much pasta. I think that whist the frame will remain strong because of all the braces (forming triangles), but the weakest part will be the single strand of spaghetti at the top (which was needed to achieve the height goal). If anything will snap, I believe it will be because the single strand will have too much side-side force applied and snap.

Our First Tower

The Seismograph

Our first deign worked as hypothesised. The triangles withstood force from all directions as remain standing. The frame will remain strong because of all the braces (forming triangles), but the weakest part was the single strand of spaghetti at the top (which was needed to achieve the height goal). It easily withstood the side-to-side forces, but the up down force applied gave it a bit of stress but nothing snapped or even reached critical bends.

All in all it met the criteria of the task and withstood an “earthquake”.

For our second design we removed the bottom internal square base, as we had stuck it to the mat anyways and it was just using money. This then allowed us to afford internal bracing which held up really well and I’m so glad we did it. It made our building heaps stronger, it removed any wobbling or stress in the main body. Only the spire continued to bend but it held up the stress the entire time and didn’t break once. We also lengthened the top 4 supports, to try and help support the spire – if we had more money, we would have made them taller.

Our Final Tower Design

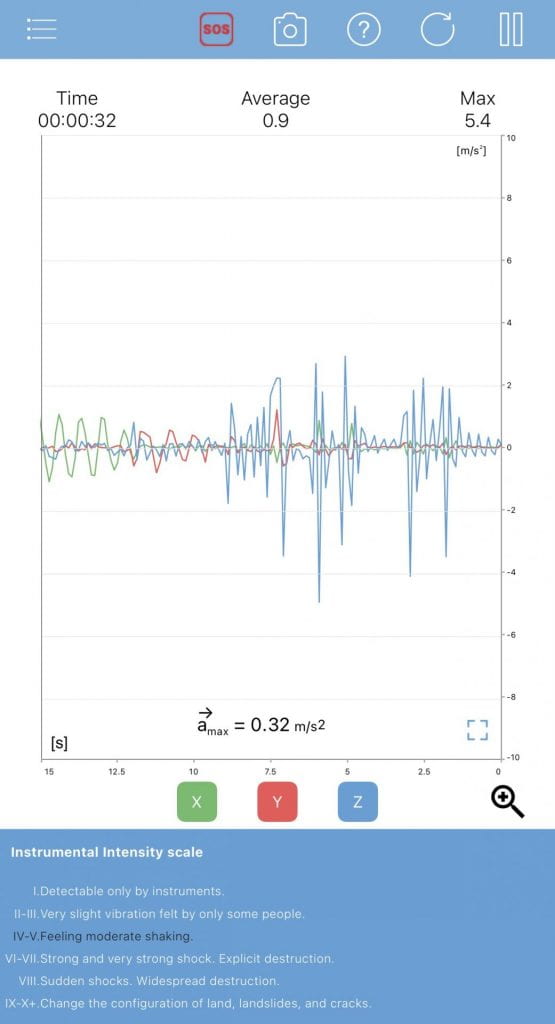

The Seismograph

It withstood an 8.9 mag, which was much higher than the first 5.4 mag. That means it withstood exactly 1500x as much energy and shocks (Because each 1 point is 10x stronger and it is 3.5 points higher).

In my group of 3 we all split into our own roles and brought our own bits to the team. We all had a high level of teamwork and communication which helped throughout the challenge. We chose to create a group “team” so that we could all share files and even if one of us was sick/not in class then they could still contribute or at least know what we are all doing. This worked very well and helped us heaps. One of my team members was very creative and helped heaps with the designing and creating of the plans for the model. This was very useful because when we needed a new design, they would be the first one to throw ideas into the conversation. Another one of us was very good at managing and preparing the resources. They were very good at snapping the spaghetti into the correct lengths, splitting blue tack and was very precise when measuring. This was very useful because it meant we had all the correct materials we needed with no waste. Finally, myself. I was very good a leadership and made sure everyone was on task and doing what they needed to do. Also, I did the hands-on part of actually assembling the model. I came in handy when we needed to actually make the model according to the diagram and ensuring we were on task and on time.

When we did this challenge, we had to use the engineering process. You can see that to the right ->

One change that I would make to this process in order to achieve a better outcome would be to put research before brainstorm. This is because I feel as if it could have been beneficial if we had already known about other existing solutions before trying to think of our own. This way we could improve others rather then start from scratch.

The Engineering Process

Another thing I would have done differently is I would have gathered all the materials before designing because when we measured out 1g of bluetack it was a lot more than we thought. Also, we didn’t realise how little 10cm of spaghetti is. This way we would have known visually what resources we had at hand, before designing.

Overall, I think that this was a very beneficial challenge and I am glad I had the opportunity to participate in it. I learnt and developed many capabilities such as leadership, teamwork, creative thinking and problem solving. I would highly recommend this challenge to any group of willing students or adults.