Our task was to build a structure that withstands an earthquake simulated by shaking the structure on a board. This structure must be 60cm tall as a minimum and the base has to be a maximum of 30cm squared. To make this structure it must cost less than $60 with 1 piece of spaghetti costing $1 and 1g of blue tack costing $1. One of the reasons this project was so important is because it can help us to be more prepared for earthquakes and cause less damage when an earthquake hits if we make all buildings earthquake safe, as well as to improve our appreciation for all the work it takes into designing actual earthquake-proof structures. Though it may not be very on our minds in Australia as we are lucky to have very little systemic activity, however, to our neighbours in New Zealand, whether a structure is Earthquake resistant is a major concern due to their increased seismic activity, so it s important to understand the process and engineering that goes behind it.

We started by bouncing around a few ideas about our project, and how we could brace it. Although nearly none of these ideas made it in their entirety, many of them were adapted and rethought for the final model, for example, although we did not build that structure on the right, we noticed that the base was very strong so we adapted the base to be built tested and tapered to a point, another idea that we completely scrapped was to put the entire tower on tracks, so it could slide around and move with the earthquake however we canned the concept due to the problem of the tower sliding off, or falling over.

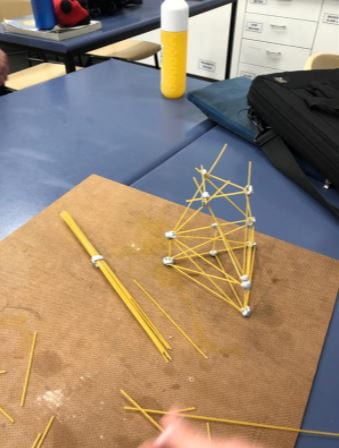

We devised this design to build, and we had hoped to stay perfectly true to it however a lot of complications arose (namely the tower falling over once every five minutes) so we had to adapt. The main problem we realised was that the top of the tower was too heavy, and due to a few uneven pieces of pasta, all the weight got centred around one area on the base, and because we didn’t make the base strong enough it kept on pushing the pasta through the blue-tack, as well as snapping it. This, unfortunately, ate through the majority of our budget as we kept replacing materials and we were only left with three dollars by the end (spending 41 dollars on pasta and 16 on blue tack).

In the future, we would 100 per cent put more effort into supporting the base structure, and making sure all of the pieces of pasta were even as it was both the weight distribution and the even strut lengths that caused our tower to snap so frequently.

Here is a video of some changes we had to make during the building process, unfortunately, due to file size I had to upload it in three parts, however, it still works.

The final step in our process was to test it, needless to say, Ella and I (as our other group members were away sick) were very worried, it had gotten to the point where I would have to attempt to fix our fallen tower every time I walked in the classroom, however on the day of our final test I had Ella to help me so we just got it stable enough to pass all the test before I had to remove the top half, for fear of it splintering, otherwise, the project was a great success and I learnt a lot about designing structurally integral buildings, even if it was mostly learning from my own groups’ failures.