Summary of Project

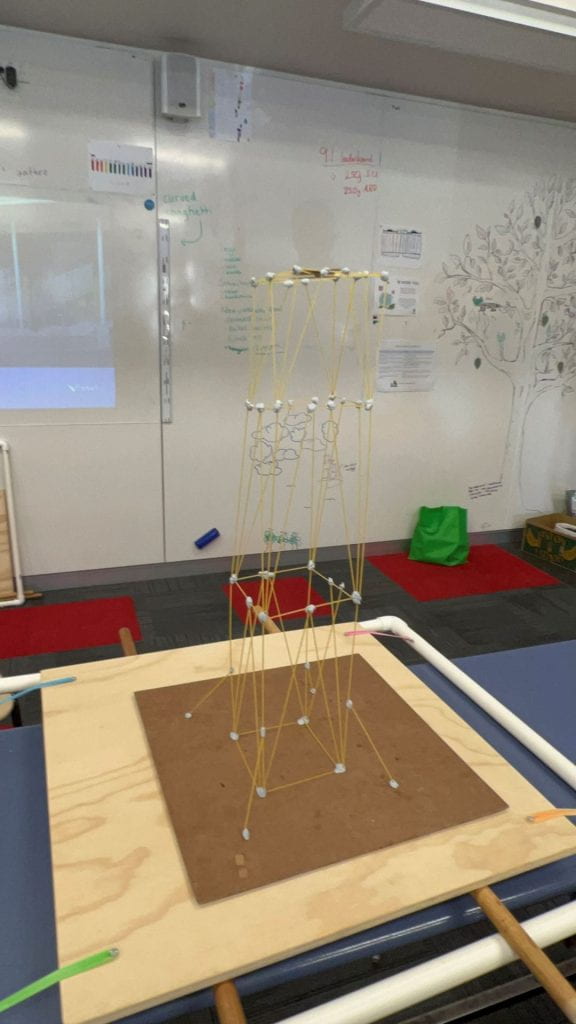

This year in science, we had the opportunity to utilize spaghettis and bluetack to build a structure that needed to be at least 60 cm tall and be able to withstand a simulation of an earthquake. This science project delved into earthquake engineering through the construction of towers subjected to simulated seismic forces. As we explored the many aspects of our design, we were able to connect theoretical concepts to practical applications, this showed the challenges faced by real-world engineers when it comes to creating earthquake-resistant towers. This project also limited us to a budget of $60, with a piece of spaghetti and one gram of bluetack costing 1 dollar each, this mirrored the constraints that engineers had when it came to material availability and budget. Through the design and engineering process, our group gained valuable insights into many aspects, including the significance of accurate design and engineering and the importance of structural integrity when it comes to building earthquake-resistant structures.

Our hands-on experience extended to the test phase where our structures faced simulated earthquakes. This process closely mirrored the rigorous testing that is done on real-world structures. Ultimately, our structure was able to withstand the earthquake, with it holding its structural integrity. Overall this project deepened my understanding of seismic waves and seismic engineering and was an amazing opportunity that I will remember and value.

Analysis of Engineering Process

Our engineering process for the spaghetti tower project showcased a systematic approach to problem-solving. Initially, we defined the challenge of creating a seismic-resistant structure using spaghetti and blu-tack. We brainstormed many design features and ideas, leading to the exploration of various design ideas. Extensive research helped us to make informed choices, considering the $60 budget and material availability. The design phase involved careful planning and adhering to the project constraints. Next was to the prototype, we transformed our design into a tangible model, helping us test and evaluate our design.

When it came to testing our first prototype, we realized that the design just took way too long to build due to all the variety in lengths of spaghetti and us having to cut them, however, we were able to fix this issue in our final prototype by only using either full or half (12cm) lengthen spaghetti to build our structure. Overall, our structure withstood the earthquake simulation fine, but could only hold one weight on our platform when it came to that testing phase, exposing flaws in our design. A major flaw our design had was its structural shape and stability due to the second layer of our structure being built up unevenly, therefore leading to a diamond sort shape on the second layer. A major improvement we would do next time would make sure that we keep the basic shape of each layer of our structure in unison, by using a ruler or something flat to ensure the structural shape, which should lead to our structure being able to hold more weight.