This term in science I worked well with my peers to create an earthquake-proof tower out of spaghetti sticks and blue tack. We were supplied with a budget of $60 to buy our materials from Mr Goor. The materials consisted of spaghetti and bluetick only. The aim was to create a building out of spaghetti sticks and blue tack that can resist an earthquake on a platform that Mr Goor shook to act like an earthquake. We had two rounds of building and two chances to try and get our building to withstand the earthquake. The criteria we had to follow is below.

- is quick and easy to assemble

- had a medium height of 60cm

- has a maximum base of 30 x 30cm

- remains standing after an earthquake, as simulated by shaking a table for 10 seconds

- is constructed from the materials supplied by our teacher

- costs less than $60 to build, given the material cost

- material cost; spaghetti ($1 per 10cm), Blu tack ($1 per gram)

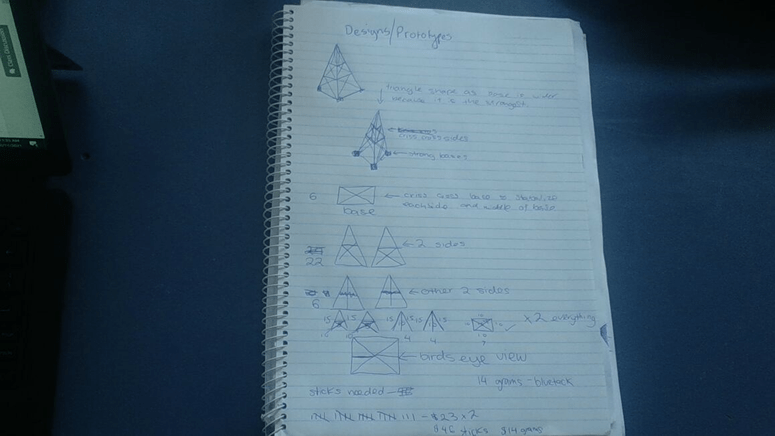

The engineering process is a sequence of steps that engineers use to help them develop and test potential solutions to challenges. The steps include finding the problem that you are solving, brainstorming ideas to generate new ideas, researching solutions, designing solutions, and creating prototypes, and finally testing and evaluating the finished product. My partner and I could have improved on our engineering process through researching more and designing and brainstorming ideas before we tested our structure.

The first thing my partner and I did when beginning our engineering challenge was gathering research and information about earthquake-resistant/proof buildings to build our knowledge of how these buildings are built to withstand such a big disaster. We learned that cross braces are involved in the building process of earthquake-proof buildings, so we made sure to include them in the structures we build. After we gained research and knowledge about the buildings, we got out a notebook and wrote down the lengths of the spaghetti sticks so we knew how much to snap off the length of the spaghetti sticks for our structure to be equal and not wonky. After we drew up some designs and measured our lengths, we got a clear space together to start making our first building. We got our blue tack, spaghetti sticks, ruler, and placemat on our benchtop with a clear space to get working. We had begun with our base and then went up from there. My partner and I were successful with our first structure as we made sure to not make it too heavy and ensured that we were using small pieces of blue tack to prevent it from breaking. Our second time making our building was unsuccessful due to our time management. We were trying to rebuild our structure and unfortunately, the spaghetti sticks kept on snapping and we could not get it right. We continued trying different ways to rebuild our building but did not realize the time. We had to put something very random quickly together and it ended up just being 60cm tall. We then took it to the test on the earthquake board and it did not break but it did not stay 60cm tall. it dropped down to under 50cm tall so we were unsuccessful.

I demonstrated teamwork along with my partner as we worked very well together and got done what we needed to. By doing this we were able to work efficiently and get all the steps completed in the engineering process. Another capability my partner and I used to work efficiently was communication. By using our communication skills, we were able to send videos and photos to each other if needed. Without using our communication skills, we would not have completed all our questions on the Stile activity with all the media we included.