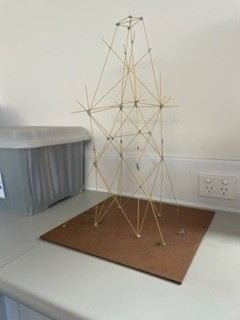

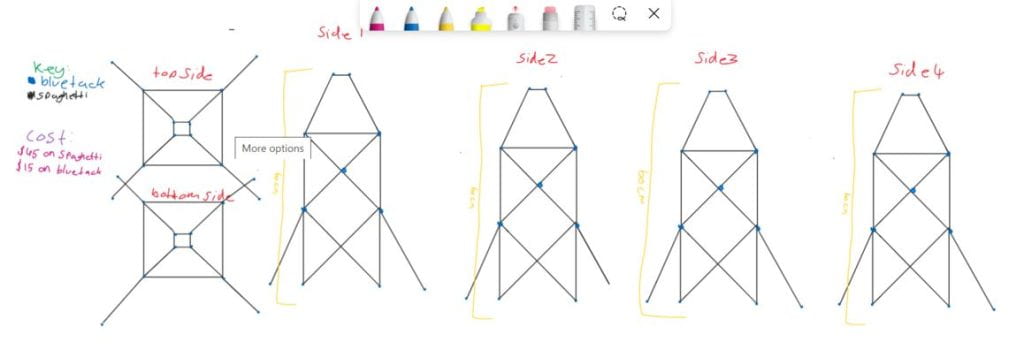

Our task was to create an earthquake resistant building out of pasta and blu-tack. We were given a set of requirements that we had to follow including that it had to have a minimum height of 60cm, a maximum base of 30cm x 30cm and a top platform that was minimum 5cm x 5cm and could hold a piece of paper. To simulate an earthquake and test if our building was actually resistant we used a shake table and shook the table from side to side and vertically. We were also given a $60 budget and all our materials were priced. This is was to help relate our project to a real life situation because architects cant just design a building with however much material they want.

My group faced some difficulties in the engineering process and we found it challenging at the start because we didn’t have all our group members. For the first 3 lessons of the actual design part 3 of our group members including me were away and couldn’t help the group. This meant that our other two group members had to build the first design and start designing our second design by themselves. The main part of the project is how we work well together as a team and that was difficult when we weren’t there. Since the first model they made didn’t meet the requirements we had to add to the design so it would have another level and reach the 60cm height.

When we first started building our final model we worked very inefficiently together and had to restart multiple times. We faced lots of problems with making our building even on each side so we had to measure all of our pasta sticks. The building process became a lot easier once we assigned everyone their own job. This meant that we could have someone measuring the pasta sticks, while other builds and someone makes sure its stable.