For the remaining weeks of Term 4, Year 9 students participated in an Engineering Project.

Aim

The aim of this project was to design and produce a building that could survive an earthquake using spaghetti and Blu Tack. The requirements were to produce a 60cm tall building with a maximum of 30 by 30 cm base and had to survive a 10 second earthquake. There is a budget of $60, with a 10 cm piece of spaghetti or 1 gram of Blu Tack equalling $1. The purpose of this project is to use a variety of design features to enhance the chance of buildings surviving earthquakes, as many across the globe currently don’t. People loose their homes due to these damaging disasters, and it takes years to rebuild. The aim of this project is to help us understand just how difficult it is to design a building that could help. Our group consisted of 4 people and we each played an important role in completing the next steps in our project.

Research

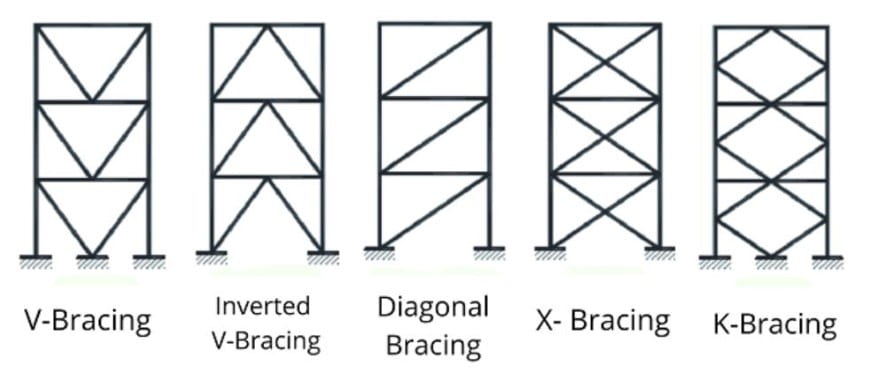

The most important step for succeeding is research. It allows us to figure out the best methods for our design. One member in our group showed a particular interest in finding different methods that engineers use today when designing buildings. Our main focus was on different structural methods that can be used within the building such as different forms of bracing. This includes the idea of x or diagonal bracing providing the most support because it allows the pressure to pass out of the building most effectively. This team member used the capability of being inquisitive. They were curious and wanted to learn about this by finding a variety of sources and sorting out the best options available. This meant that in the later stages, we could all refer back to this research. When we encountered issues with our structure, our ‘expert’ could help find the best solution. The strength of this member was their desire to learn about facts and statistics, allowing their contribution to the challenge being a variety of knowledge.

Design

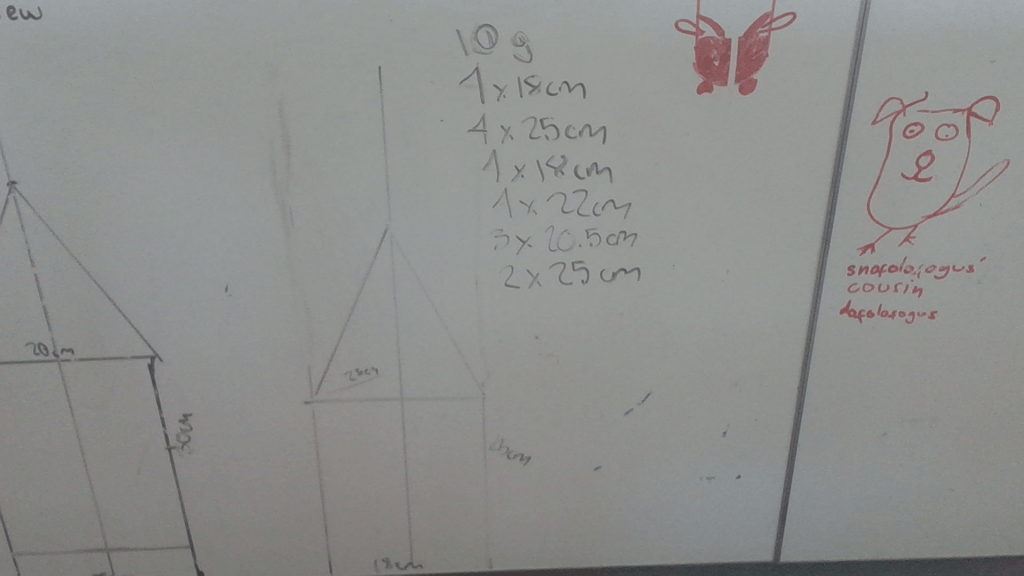

For the design phase of this process, we began by drawing possibilities on paper. We then found it hard to add measurements to our design so chose to draw life size versions on the whiteboard. One of our team members showed effective communication by discussing and figuring out measurements. While we tried drawing possible options, they would help measure out lengths and draw out our final decisions. This helped our group as it allowed us to be able to consider costs before finalising our design. They provided easy communication for our group by making sure the information we needed was easily accessible among all our ideas. They were the person who notified the rest of us if we were over budget and would then input to find other solutions, helping our group with overcoming problems. Their strength by far was their communication and organisational skills because they kept our group on track with the end goal in mind. Out of the whole project, the budget was our biggest challenge. We wanted to add lots of horizontal and vertical bracing on every face of our building, but this caused the expense to be double our budget. We had to remove most of our bracing, only leaving horizontal bracing with the plan that it would send the pressure out and down. We then added a long piece of spaghetti in the centre to try add support towards the vertical pieces. Below shows the evolution of our designs as we edited and changed them to suit the budget while incorporating our research.

Create

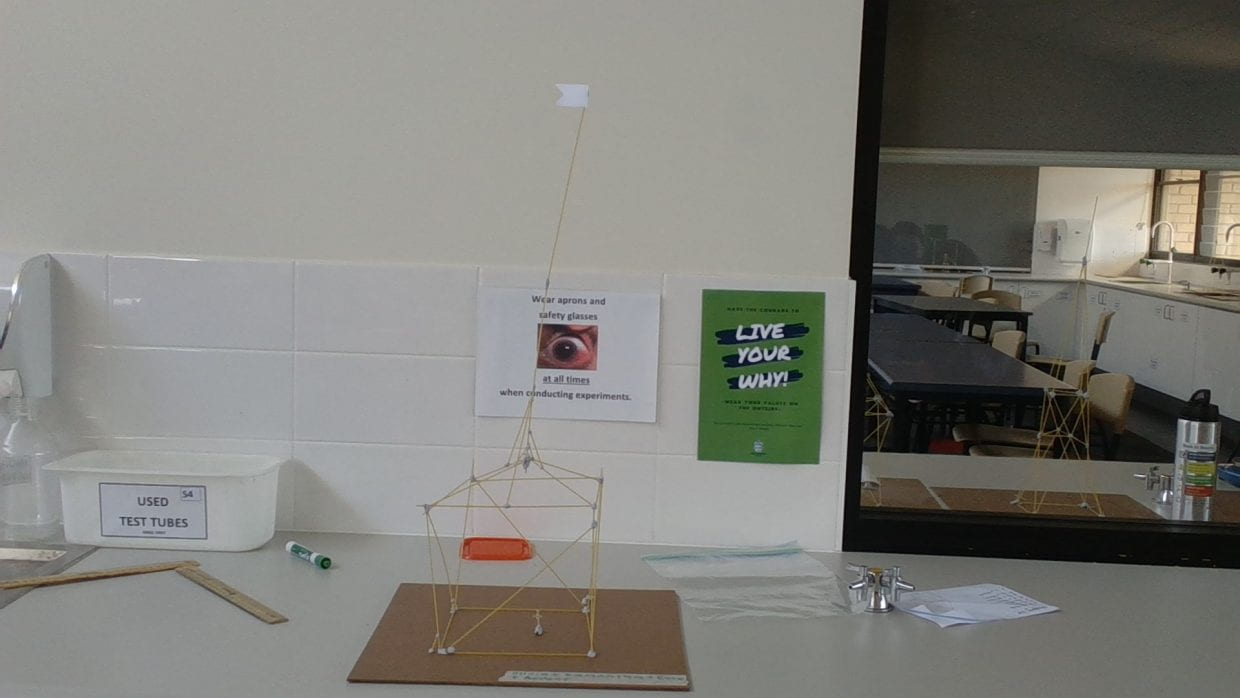

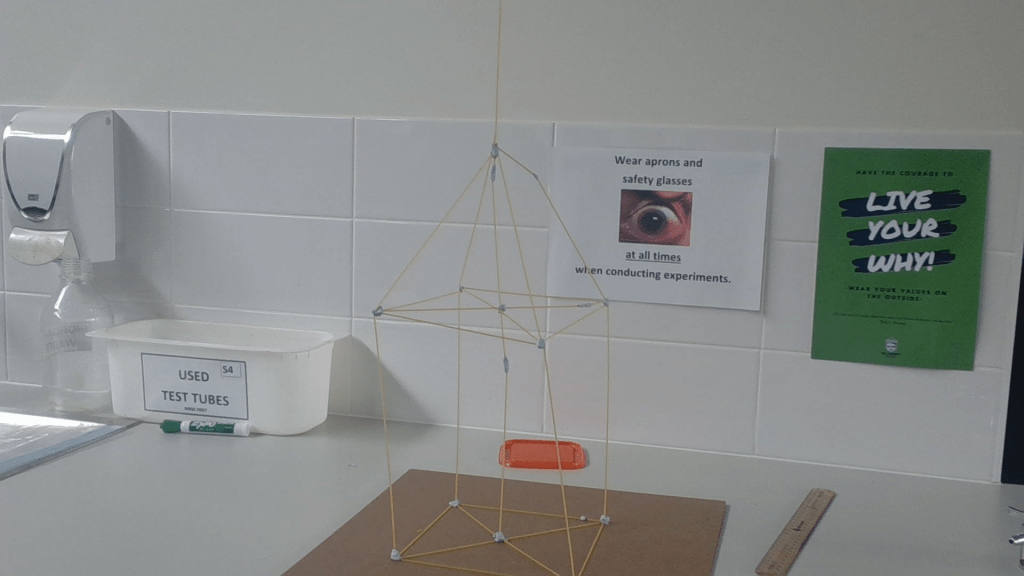

This phase of creating our building was by far the most challenging. As a group, we had decided upon our final design and created a shopping list of all the materials we needed. Our total ended up being $59.35, almost our entire budget. This left little wriggle room, we could not afford to purchase anything for last minute changes. Making a 3 dimensional object was not easy, as we discovered. This step involved everyone in our group holding every part of our structure until it was stable. One member of our group took charge in sorting out the spaghetti and preparing the Blu Tack while also providing support to our struggling building. Although it sounds simple, without them, we would not have been able to move forward at all. They showed amazing organisational skills by using their initiative to prepare our group. As we were following the plan, they ensured we were using the right pieces of spaghetti, fixed any broken ones, provided the Blu Tack and made sure all of our joins were secure. When following our original plan, we encountered many flaws. Our structure did not have the bracing that we researched in the correct locations so we decided to make a couple modifications. This included removing the centre piece of spaghetti as it was just adding weight and turning it into vertical bracing. We managed to snap several pieces of spaghetti in the process, causing our building to be lopsided. Our building could barely stand up on its own so as a group we decided to take it all apart and restart. This was so that we could find pieces that were more similar in size to prevent lopsidedness. We then rebuilt, being more cautious about snapping our spaghetti. We used all the little pieces as support for the parts that needed it such as around the base of the top piece. Below shows the evolution between our first build and the new modified version.

Test

Once we finished building, it was time to test our design and see if we met the success criteria. So far, our building was just at the 60 cm height requirement, fit within the 30 by 30 cm base and cost under $60. To succeed, it had to last 10 seconds in earthquake conditions by shaking a table. Below is the video of our building being tested.

As shown, our building did not collapse. Although there were areas for improvement, our group met the success criteria for this project. The few flaws in our design that we could recognise included how some of the pieces of spaghetti were becoming more bendy due to the amount we were handling them. To fix this, we just replaced them with other pieces. Also, some parts were becoming disconnected due to the Blu Tack loosing stickiness so we just re-stuck them together.

Rebuild

Our group found the rebuilding process quite simple because our first build had already succeeded. The criteria changed to 25 cm tall and needed a 10 cm by 10 cm wide platform at the top. All we needed to do was shorten the top piece of spaghetti. Also, we decided to trade in some Blu Tack for an extra piece of spaghetti to add one more cross bracing at the platform to be able to put paper on top of it. When tested, it also survived. Below is an image showing our final product.

Outcome

The results we gathered from this project were very positive. We were able to work as a team to design and create a building made entirely out of a limited supply of spaghetti and Blu Tack which could survive an earthquake for 10 seconds. This shows that there are ways to create these structures using different strategies and techniques. Our group decided to focus on different bracing techniques to create a strong and secure building. It is possible to build buildings suitable to withstand earthquakes but with the limited amount of materials made it a challenge. I think next time we could also look at other methods such as shapes to incorporate into our design to hopefully provide even more promising outcomes such as creating a triangular or dome structure. I think our group worked extremely well and showed team work throughout the whole process. We did not assign specific roles at the beginning of the project, but instead adapted to the changing situations we faced. I think I personally developed the ability to be aware of others. I noticed what each person seemed to gravitate towards and provided them the chance to ‘shine’ in that area. This then allowed their strengths so be used to advantage our group. Altogether, I thoroughly enjoyed this engineering project because it helped us to develop teamwork, work with each others strengths and collect a variety of ideas while also discovering how important each part of the design process is to find success, no matter the challenge. Earthquakes change peoples lives around the world, this project shows that we are capable of changing this.