For the last few weeks we have been working on a project based around what we had been learning this term. This term we had been learning about plate tectonics and the structure of the earth.

The Aim.

The aim of this project is to build an building using limited resources which can withstand lateral and longitudinal forces.

The Rules

Dimension Rules

- Base has to be a maximum 30cmx30cm

- The height has to be a minimum of 60cm.

Resources

- 10cm of spaghetti=$1

- 1g of Blutack=$1

Overall Budget is $60

Outcomes

The outcome of this project was to find an efficient building type to withstand an earthquake test using limited resources. During the testing we found that, buildings that were pyramids were much stronger than those that were not. We saw this in other groups where those that had building that were rectangular fell much easily compared to those that are pyramid shaped. We also found that Trusses and Cross braces where very useful in dampening or helping a building withstand the force of an earthquake. We also found that Trusses in a building meant that it would sway and move less as seen in design 1 and then in design 2 where we implemented Trusses. One of the main outcomes was that we were able to find a cheap building design with limited resources that could withstand a test which consisted of P waves and S waves.

Improvements in the design Process

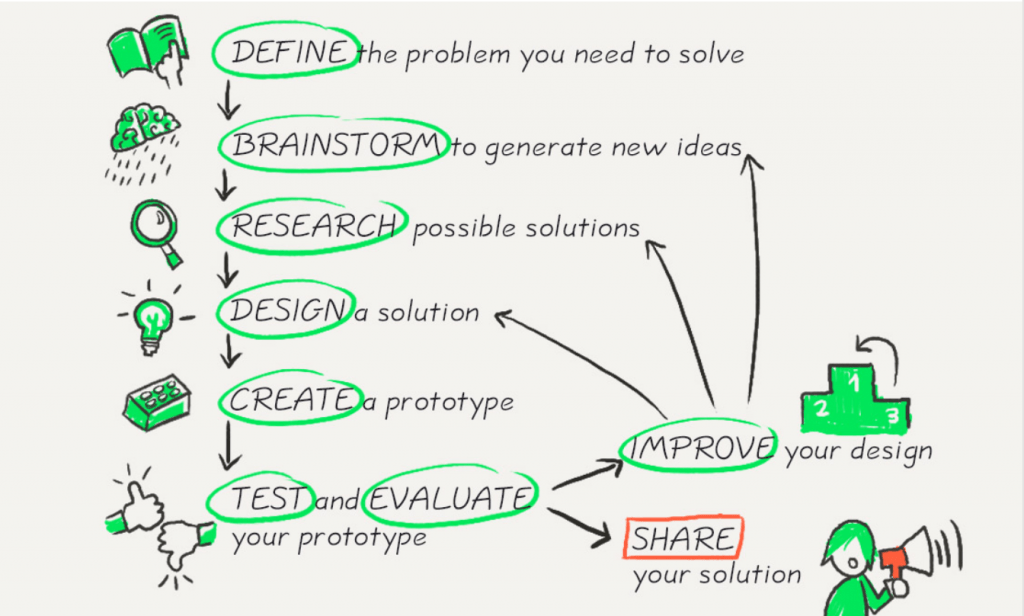

During this Assessment we had to follow a process known as a engineering process. It stated that we had to understand the problem -> Brainstorm Ideas -> Research different solution -> Design a prototype using the research -> Create the prototype -> Test it and then improve it -> Create and Test new design based on Test 1. This is the process we used to create our spaghetti, earthquake proof building.

I believe that we can do changes to the engineering process to improve our end product and improve the withstanding force of the building. I believe that we could improve the engineering process by adding more testing. During the prototype building, we would have liked to try multiple designs to see what parts of what would have been better. This means that we could have done multiple prototypes and multiple tests to then help us build our end product. I believe that only doing one prototype meant that we were only testing 1 idea and that any changes to that may be experimental and we don’t know how it may affect the building as it may have not been tested. While we learnt from the research that Trusses is a better option that is more efficient that Cross braces, adding it was technically a risk as we had not tested it before and we did not know how it would end up. While it was a good addition, it may not be for other people and any changes to occur in a final design, I believe should be tested beforehand. This would improve the quality of the changes added to the end product and this would improve the outcome. Another way in which this process could be improved is through after the testing of the prototype, any peer feedback could be given. Usually large projects throughout the world need feedback from other people and other businesses to get their thoughts on the project and how it could be improved. Peer feedback could be added as a new section after the testing and evaluating to get other group’s thoughts on their project/plan of the earthquake proof structure. This would help groups in their outcome as they would be able to get feedback from other groups and 2 different group’s opinion may positively shape one group’s project.

My Team

Royce strength was his organisation and his resilience. This coupled with his strong mathematical skills allowed for him to do all the calculations need for our group. As the cost calculation were essential in starting the building, his organisation meant that he always delivered on time meaning that we were able to stick to deadlines. Even when we changed our design multiple times, Royce was always happy to do calculations for the group as many times as we had to do. He was also the main builder due to his resilience and how he never gave up. This helped us pull through even through the large problem where the height was not enough in our first design. Royce was able to pull us through hard situations and was very reliable so we were able to finish the project.

Thenuk used his logical thinking to evaluate the advantages and limitations for each design. He was able to do this efficiently and we were able to single out better designs as a result of this. This meant that as designers, we were able to know what improvements we were able to make to further improve it. Thenuk also made sure that we were not going off task and as a result, we were able to achieve deadlines and the group was organised. This is why we named him “Reality Check”.

Tim was very collaborative and always took into account all the ides to mould them into one design. Tim was the one that took our rough sketchers and turned them into proper designs on which we could base our buildings on. He was able to use his strength of collaboration to listen to everyone’s ideas, and then incorporated into one design which everyone was happy with. This was also coupled with the skills that he learnt in woodworks to draw strong sketches that were able to help the builder. This meant that we were given strong designs to build off of, this improved the quality of the structure that we built.

My Job in the team was consisted mostly of Designing and creating of Ideas. I used my strength of creativity and curiosity to research and think of different ideas and ways to make the building as stable as possible. During the design process, I did a lot of research and brainstormed many different ways in which we could build the structure so it can withstand the testing. Some of the things that I contributed was through the idea of the pyramid and the cross bracing. I was also very conservative meaning I tried to be as efficient as possible with the materials that we had. This meant that I helped the group be more efficient and use as less materials as we can so that the project can be as cheap as possible while also achieving the aim.

Whole Group:

All of these strengths allowed for a very cohesive group that was able to work together. While each one of us had our own separate roles, we always helped each other with any other jobs like building and designing. I would say that I generated the Ideas, Thenuk would evaluate them, Tim would turn them into useable sketches and then Royce will calculate the cost and lead the building with everyone else helping where they can. This lead to a very strong an efficient team that was able to meet deadlines.

The Question and its importance

Earthquakes are destructive seismic forces that can severely damage areas throughout the world. They occur many times every years and sometimes, destructive earthquakes displace and kill thousands of people in the affected area. The challenge that we have been given is to produce a earthquake proof building which is able to be built in a low and limited amount of resources and money. It also has to be a certain size. This is relevant in the real world as countries have a limited budget if they are to build multiple earthquake proof buildings and they needs to house a large portion of the population. So the aim for governments is to house as many of the population in earthquake prone area’s in the cheapest possible amount of money. Developing countries like Nepal that have low budget for infrastructure do not have enough money to pay for expensive earthquake proof buildings. Almost 98% of all building will collapse in Nepal if an earthquake occurs and this would cause mass destruction, a considerable amount more than developed countries like the US. This shows the need for cheap and reliable earthquake proof buildings. Also many countries may only have access to only a certain amount of resources, especially developing countries that may find it to be easier to use locally made materials. This is one of the main reasons why we are building a model for a earthquake proof building with low expenses and with a price limited of under $60 and how we are only given limited resources of blutack and spaghetti.

Research

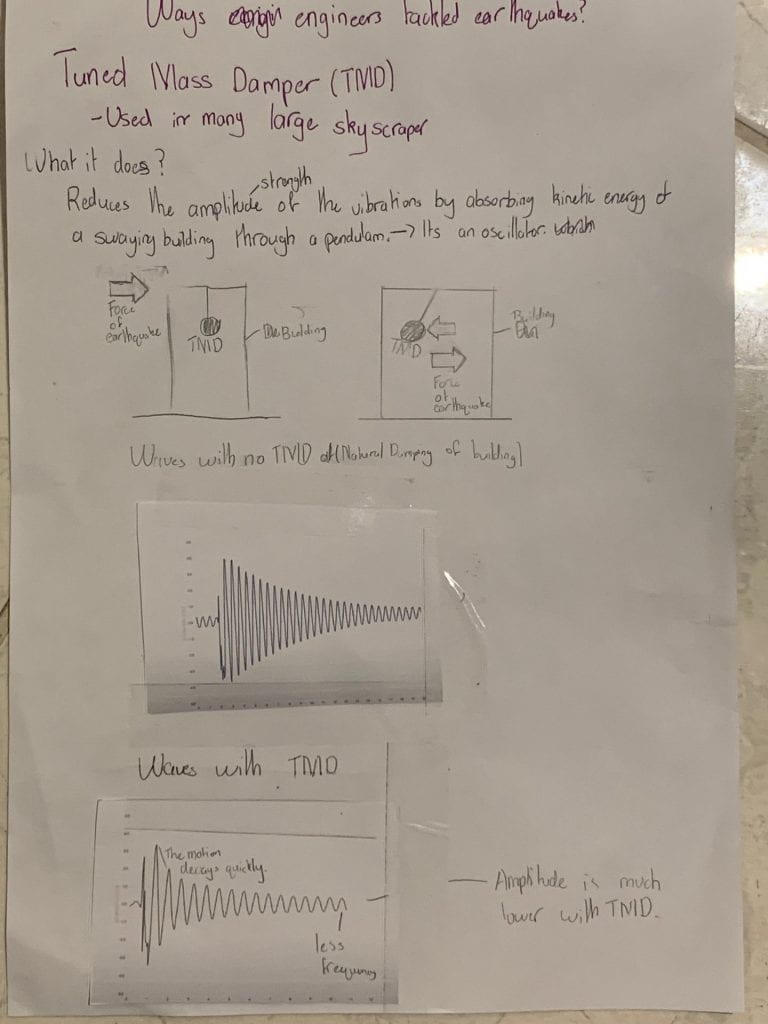

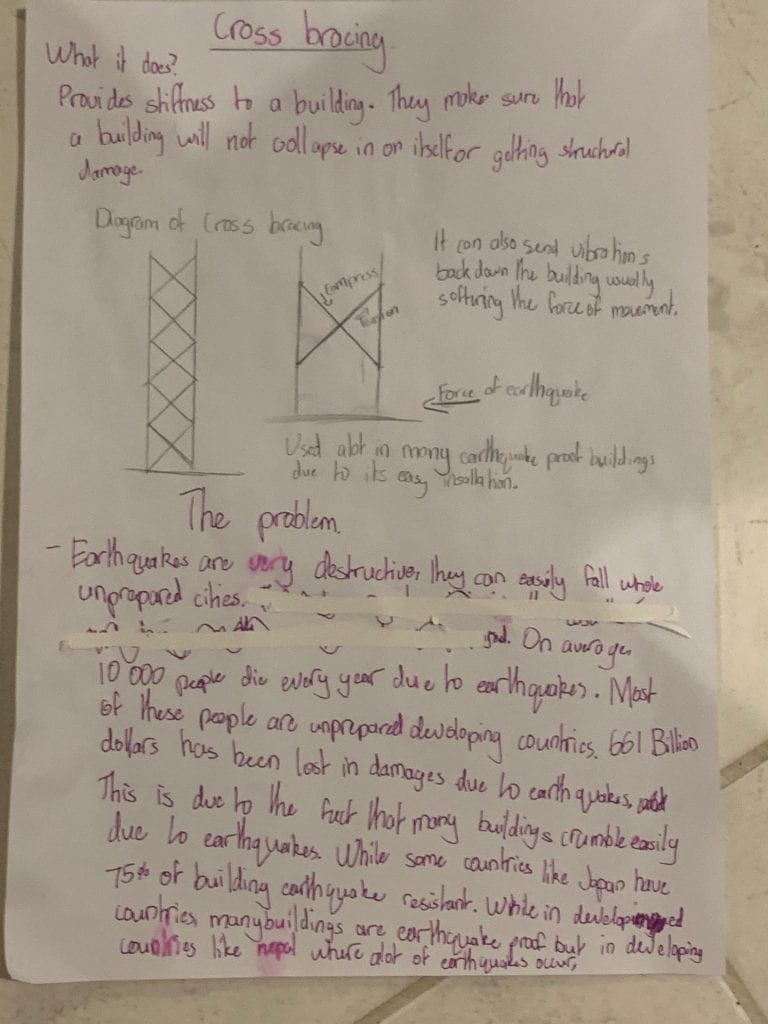

The second stage in the engineering process was the the research. During this process we looked at different ways that engineers tackled the problem of an earthquakes without the limitations of resources or money. Some of the research that I did can be seen below.

Though most of this research was mostly not relevant as many of the ideas were not possible with the materials. The only one which I believe would work in context to the project would be Cross-Bracing as that would be possible by putting the spaghetti in a “X”.

Brainstorming

As we found that the above research were mostly irrelevant in our context, we found that we had to do further research on what we could do using the Spaghetti and the blutack. We did brainstorming and found multiple ways in which we could incorporate earthquake proof mechanisms in our building. This included using a pyramid as it was more structurally stable, shear walls and using the weight of the blutack. The research can be seen below…

We incorporated this research into the next stage which was our design!

Design

During the designing stage, me and Thenuk worked together to think of ideas which would incorporate what we learnt during the research period. We had many different ideas like a dome or a rectangular building, but they were not as stable or they were not able to fulfill the height criteria. In the end we decided that a pyramid would be a strong shape to use through the research we found. We also found that we needed weight at the bottom and it to be lighter at the top. We decided a design that would be able to fulfill this and that would be able to fulfil the height needs. With the help of Tim and Royce we were able to decide on this design.

We decided that a wide base was very important in a building not toppling over. We also had to fulfill the height criteria of 60cm. As can be seen above, we have incorporated both of this in with a pyramid shape. The next step in the design process was planning the price of the design. Royce calculated the price of each strand of spaghetti and blutack using his math’s skills. Royce found that this design was just under $60 which meant that we had achieved our target which was essential in choosing this design over a normal pyramid which Royce calculated to be much higher than $60. In the end Royce found that we needed $41.66 of spaghetti and the rest would be more than enough for blutack.

Building and Testing->Evaluating

Building

During the building process we found that our original designs were not able to reach the height and therefore we were not able to fill minimum height of 60 centimetres as a result of the high expenses. This meant that we had to change our design during building to meet the deadline which was that period and for it to get tested. We also found during the building process that our original design was too expensive as we found that we were using a lot of money to make a large and stable base. We found that our design was not structurally stable enough and we had to add additional spaghetti which meant it was over budget.

We had to change our design on the spot so we still maintained the pyramid shape, but to be more cost-effective we made the base smaller and did not add the slant which was seen before. We also used the extra-spaghetti for cross-bracing to stabilize and add structure to our building which was not possible before. We were also able to complete the criteria of 60 centimetre height so now it will be able to get tested. As this design was made and decided in a very short period of time, we did not expect it to do very well but we also thought it meant that we would have a lot to improve in our final design.

Testing

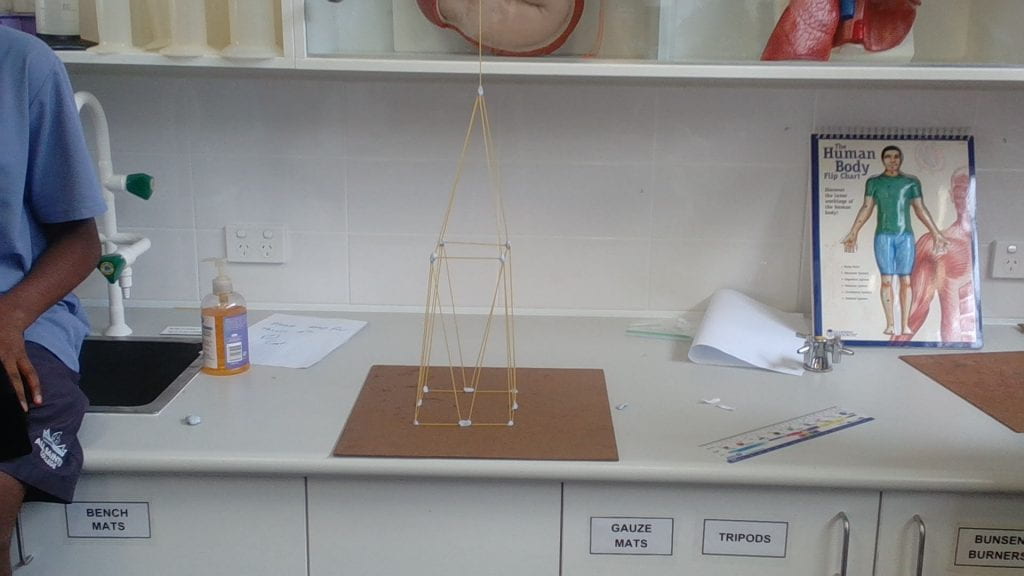

The next step was the testing of our prototype. This was a test done by Mr Goor where a moving table is placed under the building. The Earthquake simulation was based on mimicking Primary and Secondary waves. We can see that test occurring above. Surprisingly unlike what we thought, the building did quite well. The building did well in the primary waves yet it struggled during the secondary waves and in the end, one of the connections broke.

Some things that well in our first prototype was that it was that it successfully fulfilled the criteria of the measurement and did surprisingly well during the testing. Some things that we believed as a group that we could improve was amount of movement or distortion that the building was doing during the testing as seen above. The movements were quite considerable and could be a place of improvements. Also some connections could be strengthened further as the connection on the top broke during the testing which in the real world would be disastrous. Another limitation of this design was that it was too expensive and was a bit over budget. While this was a prototype so it did not matter, it was not acceptable in the final build. This was one of the major flaws of the design which we had to fix.

New Design

The next step was to think of a new design based on the testing. Are new idea had to address the expense and the swaying problem that we found with our initial design. We found one change in our design that would positively impact all of these limitation. This was the introduction of Trusses. Trusses works in a similar way to Cross-bracing but is even more structurally strong and does not allow for much distortion at the same time. It is made up of equilateral triangles. Not only did this change improve he problem of swaying but it was also effective in lowering the cost of the structure. As there were less connections and places where blutack was needed compared to cross bracing, this lowered the need of blutack and therefore lowered the price. This helped in lowering the cost of the building considerably and making sure it was under 60 dollars. We also in the end, had extra blutack and this as therefore used to strengthen important connection points. We can see how the change of Trusses was useful in solving many limitations of design 1. The new design can be seen below.

The building of this design went very successfully and to plan. We then tested the end product.

This structure was therefore successful in meeting the criteria and was able to withstand the final testing. This shows that we have successfully answered the problem and have achieved the aim of creating an earthquake proof building using limited resources.

Conclusion

This project has strengthened many of my capabilities like Resilience, Organisation and my Problem Solving. I have learnt how to stay strong and resilient in the face of deadlines and problems and how through a calm and steady mind, you can problem solve your way out of it. I learnt how to meet deadlines as that is not something that I have done for one assessment over a few weeks with multiple parts due at different times. I enjoyed this project and collaborating with my group and freinds to create a fun and cool design which is relevant in the real world.