Project Overview:

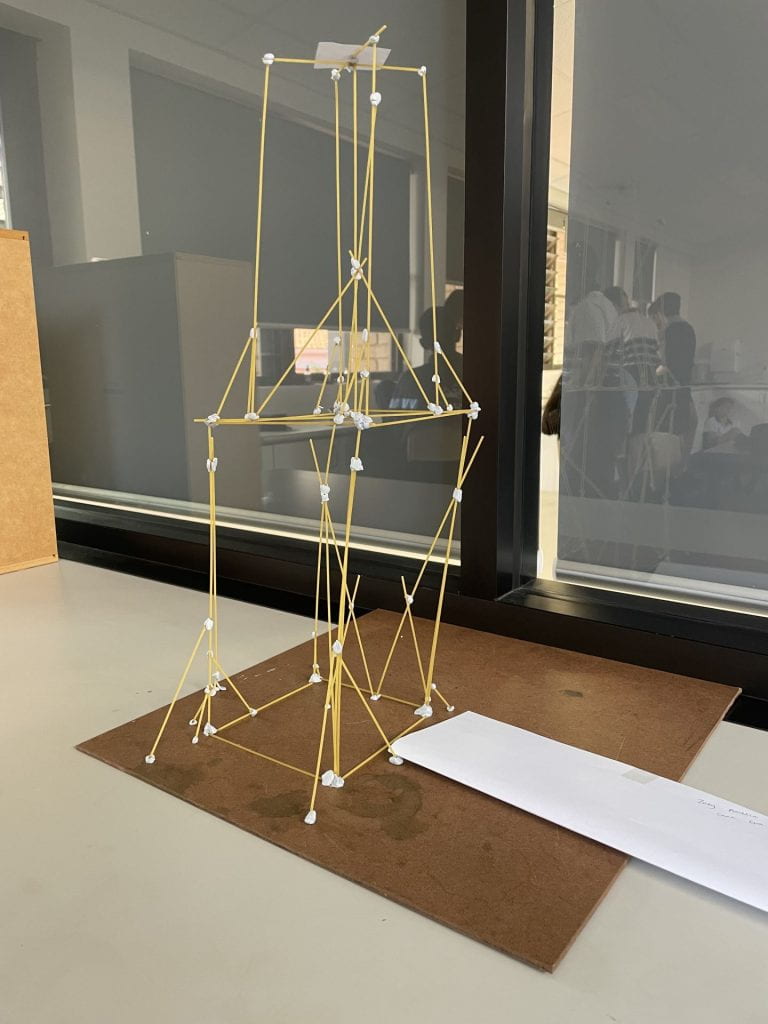

For our final assessment in Science this year, we were put into groups and tasked to design and construct an earthquake-resistant building made out of spaghetti and bluetack. This tower had to meet the following criteria:

- Quick and easy to assemble

- Has to have a minimum height of 60cm

- A maximum base of 30 by 30cm

- A platform on top which is at least 5 by 5cm.

- Go through earthquake simulations of P/S and surface waves for at least 10 seconds

- Costs less than $60 to build as 1 piece of spaghetti is $1 and 1 gram of bluetack is $1.

This project was a great opportunity for us to experience real-world examples of how important it is to be innovative in our designs. It taught us how much an earthquake can have on people’s lives and encouraged us to work out of our comfort zones with new people. My group involved Me, Amelia, Kanin and Ridley. It pushed us to use our communication skills and collaboration to build the most effective building we could have.

Engineering Process:

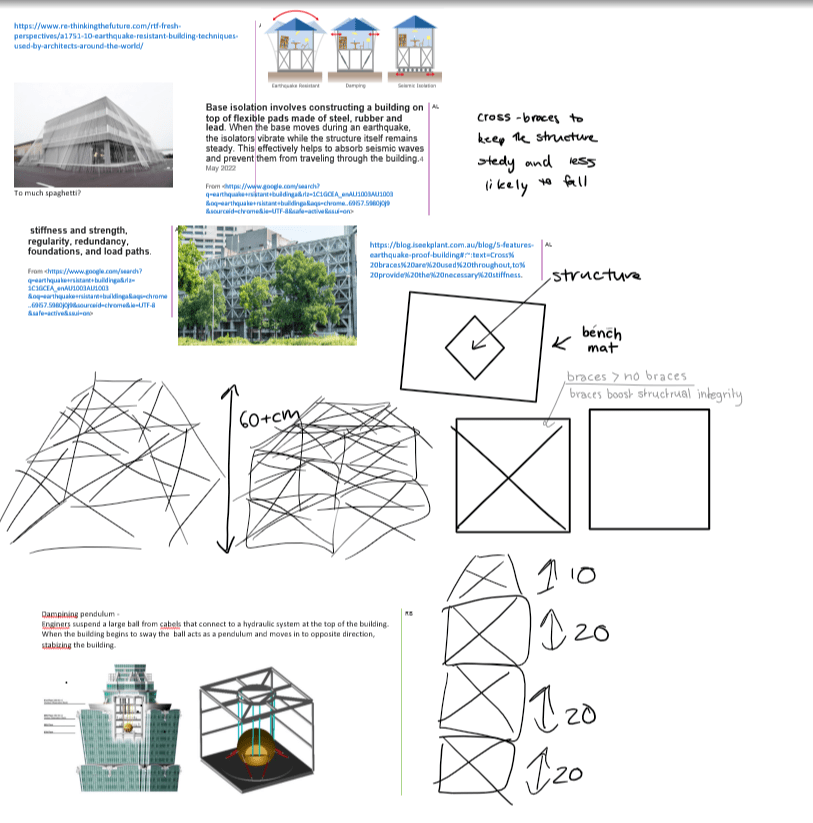

The first step in this process was to go through a design sprint. This involved us making random groups and having 50mins to create our very first building. We only got 30 sticks of pasta. This was a scary experience but our building didn’t stay up. This was an opportunity to fix our design and try something else. Our main goal in this was to create height instead of stability because it would give us the most points. Before we were allowed to start our final design we went through an engineering process to design a prototype and test if our main strategy of cross bracing would be effective.

The first step was brainstorming

The second part of the engineering process includes defining and research. In our research we found that the most effective ways of earthquake resistant buildings was to cross brace and use base isolation. With our limited supplies, cross bracing was the easiest and most cost effective option. Our building was specifically designed to be triangular because this would evenly distribute the weight and damage throughout the building. Cross bracing also distributed energy from the earthquake throughout the whole building. The brace walls had minimal shaking compared to non-cross-braced walls. This shows that the cross-braced walls boosted structural integrity a great deal when compared to a structure with non-cross braced wall. We ended up with a building of 84cm which was 24cm above the height minimum. We first started with a small prototype where we compared a building with cross bracing and one without

The building with cross bracing held up much better and was much sturdier compared to the one without. This persuaded us to make our whole earthquake building out of cross bracing.

I think our group worked extremely well together and we all had separate roles which played to our own strengths. We collaborated extremely well and all helped each other. We only ended up using $45 and created a building with a height of 84cm and it withstood all earthquake simulations and even being tipped upside down. I think our building was extremely stable and secure especially after multiple tests.

I overall really enjoyed this project and it taught me valuable lessons of real life.