Brief summary of the project:

The goal of this project was to create and design an earthquake-proof building made from spaghetti and blue tack. If the building was able to withstand the shaking, weights were added in increments of 50g. We started our project by researching what features of earthquake-proof buildings assisted in making the structure more stable, and resistant. We then used these features in our design and build of the spaghetti structure. After a lot of re-designing and discussing my group finalised and decided our design. We were then given 30 minutes to make the tower. We then tested the durability of our tower by shaking it and then adding the weights.

Overview of the engineering process:

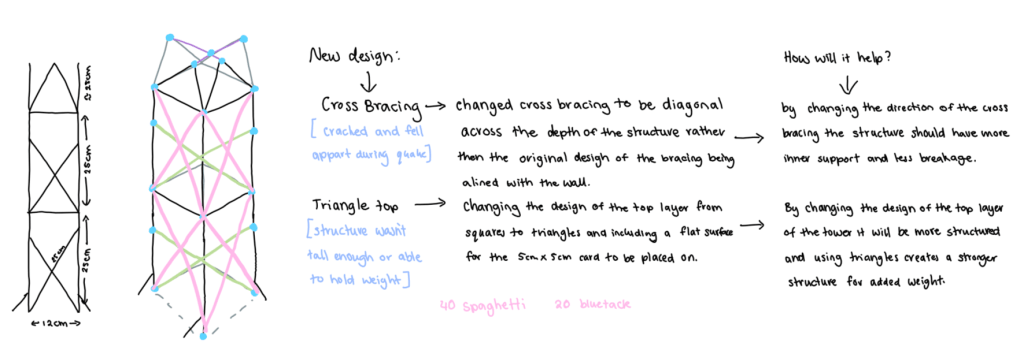

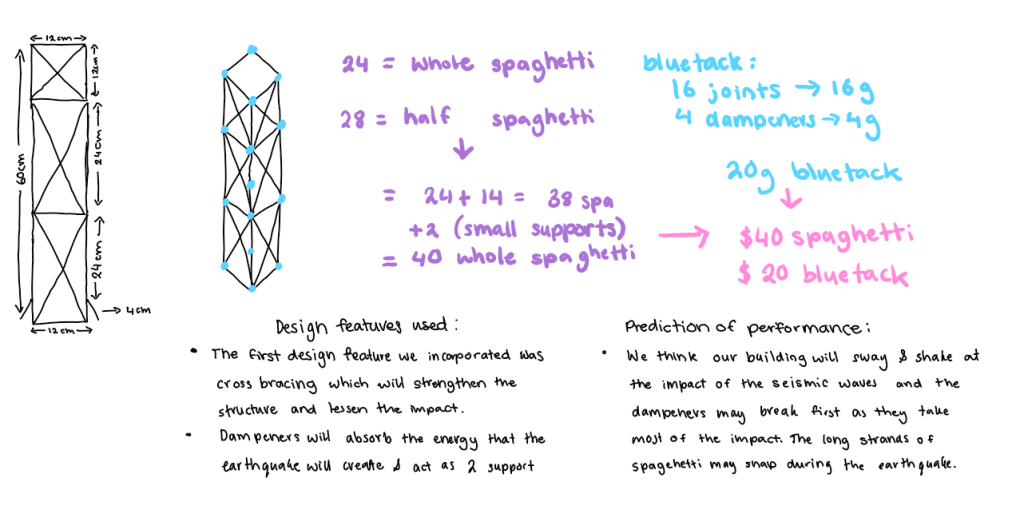

The engineering process that my group used was relatively successful as our tower was able to withstand the shaking and could hold up to 150g of extra weight. We first researched different features in earthquake-proof buildings and how helpful and successful they were. Since we had a limitation on how much pasta we could use we had to choose two features: bracing systems and dampeners. We chose these two features as they were not only one of the most supportive features but were the easiest to make and used as little spaghetti as possible. We thought that our first design would be strong as we used both features, but when it came to testing the tower was too short and one of the cross-bracing systems snapped and the whole structure began to shake/wobble. With this setback, it took a lot of time and thinking to come up with a better and stronger structure that wouldn’t snap and that would reach the height minimum. Once we found a new design which had the cross-bracing system on the inside we decided to re-build. We didn’t measure our pasta sticks correctly so the structure was even more wobbly, tilted and uneven. My group had a long think and discussion over what we should do, we went back and did some research and found that we should have two sets of dampeners, a triangle top and stronger cross-bracing systems. We finally made our finished product and when it came to testing it didn’t collapse or snap, and we were able to hold three weights until they slid off.

My groups collaboration:

I believe that each group member contributed relatively evenly, as we all understood what needed to happen and how long we had to complete the task. The table that we first created, which was used to appoint roles in the group was not looked back on or used very often. Alison was the Project Manager, Jessica was the Equipment Manager and I was the Speaker and Reporter. Not using the original table all the time helped us as none of the roles were specific to what our strengths were, and what we knew we could excel in, we also managed to do well in the task without it. I also think that not using our designated roles allowed us to collaborate more efficiently and effectively.