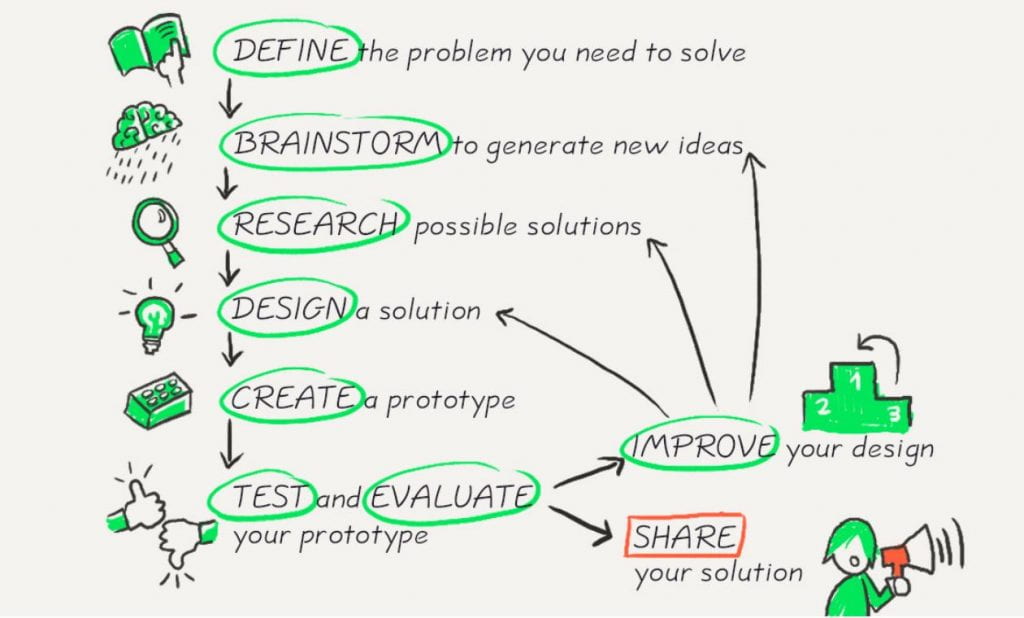

Engineering Process

The engineering process is a sequence of steps that engineers use to help them develop and test potential solutions to challenges. By using this process to help create our project we could learn how this works in the real world.The first step was to define the problem we needed to solve. We needed to identify the problem, describe the intended outcome, and explain the success criteria of the engineering challenge.

The challenge was to design, create and build an earthquake resistant structure using spaghetti and blue tack. The building needs to be able to withstand a major earthquake. This is important because people need quick and easy ways to build a stable structure with limited resources and money. We were hoping that it fit into our budget, is a solid and well-designed structure and withstands the force of a major earthquake for at least 10 seconds. The structure needed to have a minimum height of 60 cm and a maximum base of 30 cm x 30 cm. We wanted the structure to absorb the energy and not collapse or break. And overall, it needed to cost less than $60 to build.

The next step was to research possible solutions. We listed solutions to the problem, described how they could be implemented and why they would be successful, and then justified why it was the best solution.

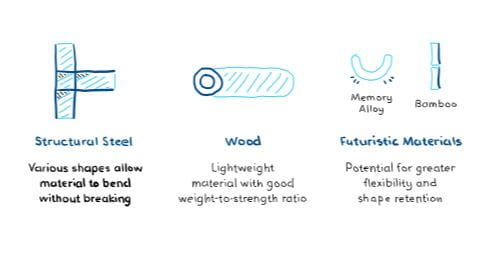

Our research showed what shapes were best to build a structure. The dome was the best shape for an earthquake resistant however we were using spaghetti, so we had to improvise and use a different method. We also learnt that in an earthquake the taller the structure the better. Because of this we knew we wanted a lot of our spaghetti to go towards the height. Other things we learnt were that when designing the structure, you also want to have the weight and strength equally balanced on each side. Cross braces are also really important as they provide the necessary distribution of force to enable a building to move with the vibrations. They send the vibrations back down the structure, softening the force.

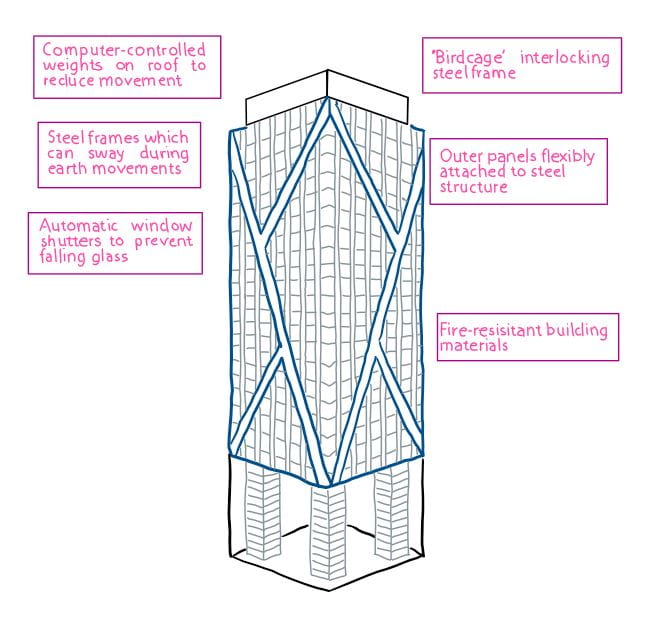

To help us create the best possible design we looked at what engineers in the real world do to tackle this problem. As mentioned above, there are many different ways to create an earthquake resistant structure. Earthquakes happen very regularly especially for those who live along a plate boundary and many buildings are destroyed. Engineers have come up with many different ways to build an earthquake resistant structure that is quick to build and inexpensive while preventing it from not just collapsing but also being damaged enough that it would be costly to repair. One way they have done this is by creating a fuse. When an earthquake occurs all the force is directed to the fuse which is then destroyed. But the damage only occurs to the fuse meaning they can just replace it. Scientists and engineers are also developing new materials for building these structures.

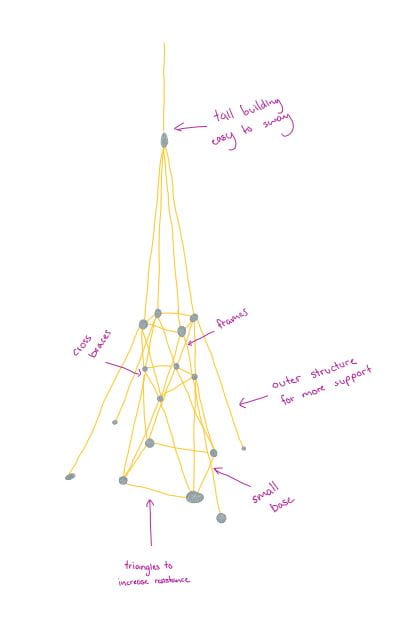

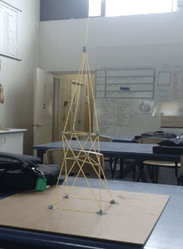

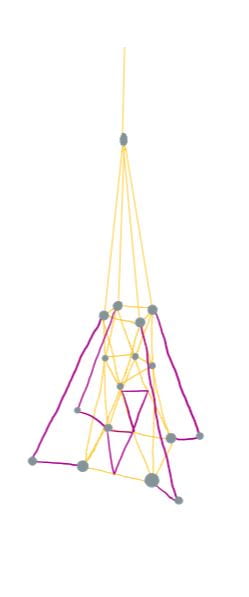

After completing research, we moved on to designing our own building. We drew up multiple designs combining our chosen solutions into one. Our structure consisted of a lot of cross braces with an interlocking frame. The cross braces were important as they provided the necessary distribution of force to enable the building to move with the vibrations. The frames will sway during the earthquake meaning the structure will move rather than crumble. We decided to use a taller structure with a smaller base as it means the building is less stiff and will be less prone to collapsing. We also used triangles as they offer increase resistance to twisting and makes the building sway less. By also adding an outer support structure to the building it stabilized the base and prevented it from snapping. Our design used a limited amount of spaghetti as we wanted it to be light and flexible rather than solid and heavy.

At this point our total building cost was $48.70 out of our $60 budget.

Now that we had a design drawn up, we began to build. It was to say the least a very entertaining experience. Our spaghetti was constantly snapping before we had even begun to fix it onto the structure and the blu-tack did not want to hold the spaghetti together. It took a while, but we finally built our structure.

And then began the testing stage. To test how well our model withstands an earthquake, it was placed on a table. And the table was shaken for 10 seconds to simulate a quake. Our structure withstood the earthquake really well. As recorded on the device the simulated earthquake was at the highest level meaning extreme vibrations and major devastation. Other than some shaking around the middle of our structure we had no breakages or collapse.

After the first test we went back and reflected on what we had done. Our structure had many advantages such as that it was cost efficient, met the design requirements, and met the performance requirements. However, there were also limitations such as the design in terms of space usage, the angle of the building and that it was not quick and easy to assemble.

We then came up with ways to improve our initial design. Our building was already structurally sound and could face a catastrophic earthquake with no damage. However, we decided we would add more braces and some more support. We didn’t secure the spaghetti to the board as we still wanted the structure to by flexible so the building would sway rather than collapse. We also added extra support on the side of our building because it supports the upper parts of our building as this area of our building has the least amount of support.

We then conducted a second test in which the earthquake simulation had even less of an impact on our structure. There was no damage made to the structure of the building, nothing broke or collapsed. This time the roof did not shake as much as it did the first time as there was more support from the new pieces of spaghetti leaving the roof and building with no damage done. The new cross braces which were only attached to the structure instead of the floor provided support to the building and remained flexible instead of making the building stiff in which case it would have collapsed.

I think we followed the engineering process really well and that our results were an indication of that. However, I think that if we had changed the process to include a reflection on the research and create multiple prototypes, we would have been able to narrow down faster the right solutions to our problem.

Collaboration

Our group cooperated really well together. It took a while, but we eventually worked out our roles within the group, what skills we each had and what exactly we could contribute to the group.

We had someone focusing on the financial side of it. So, they were responsible for financial matters for the team, keeping track of the money spent and calculating the amount of materials we had used so we could know how much we could still get. We had someone being the technology director and they were responsible for collecting / presenting research, data and all the resources and photos we had gathered. And we had someone who was in charge of supervising the construction of the building, the collection of the resources and that everything was packed up and sorted at the end of each lesson.

Each group member really took on their role and did it to the best of their abilities. Our finances were calculated from the beginning which meant that it was really easy for us to know how much left we had to use. All of our data was collected and organised well, so it was easy to find and use. And all our resources and equipment to make the building was kept track of.

For this project I took on the role of project manager. So, I basically made sure that everyone understands the challenge and keep the team on track and organised. I like to lead by example, so I will be at the front doing a lot of the work and pulling the team with me. However, for this project I took it from a different angle and tried to lead from behind. This meant I was there to support, encourage and lead in the right direction rather than do the work all myself. At the beginning this was really difficult, and I struggled to step back but by the end of this project I had really improved and because of this I learnt a lot more about my group members and this project than I would have.

Our Project

We were given the task of creating a design for an earthquake resistant building. Along with this task, we also had to go through the steps of an engineering process in which we had to evaluate the effectiveness of our design through experimentation and propose ways to improve our design.

Earthquakes can have a devastating impact on the people in the area and the places surrounding it. When an earthquake strikes, buildings are often destroyed or damaged. Many people can be injured or killed by falling rubble. And many are left homeless. It can take a very long time to rebuild homes after the disaster. By doing this project we can learn not only about the engineering process but also about earthquake resistant buildings and what is happening and what can be done.

We were given a design brief at the beginning and a list of materials. We had to design a building that would withstand a major earthquake. And we needed to design, build, and test a small-scale model that meets the following criteria:

- is quick and easy to assemble

- has a minimum height of 60 cm

- has a maximum base of 30 cm x 30 cm

- remains standing after an earthquake, as simulated by shaking a table for 10 seconds

- is constructed from the materials supplied (spaghetti and blu-tack)

- costs less than $60 to build, given the material costs (spaghetti – $1 per 10cm) (blu-tack – $1 per g)

We then began the engineering process. This was a set of steps to help us design, create, build and test our structures. The process was fairly simple however a lot of detail needed to be put in to achieve a good result. The part I found the most difficult was the testing part. The actual testing was really fun as we just got to shake an bang the table until the device recorded the level of the “earthquake”. However as our structure did not collapse or even suffer any damage, we did not have a lot to reflect on other than that our design worked really well.

When it came to building our structure we had a lot of trouble as the spaghetti was continually breaking. We also weren’t sure if our design would actually work once we started building. But we managed to build it with barely any issues

In the end I think we not only accomplished the task we were set but went into a lot of detail and learnt heaps in the process.