Our challenge was to build a tower out of spaghetti and BluTack that could withstand a simulated earthquake according to the criteria:

- Is quick and easy to assemble.

- It is a minimum height of 60cm.

- It has a maximum base of 30cm x 30cm.

- It is under the budget of $60. 1 gram of BluTack costs $1, and 10cm of spaghetti also costs $1.

- Must stay standing after the simulated earthquake.

We took on this challenge by moving through the design thinking process. This process involves defining the problem, brainstorming ideas, researching possible solutions, designing a solution, creating a prototype, then testing and evaluating your prototype. This process is then repeated multiple times in order to achieve the refined and improved outcome.

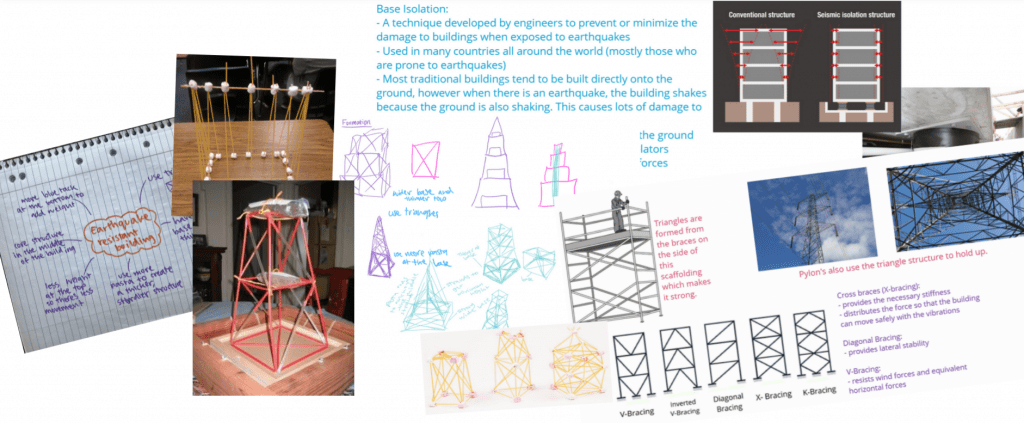

Once our group had defined the challenge, we brainstormed, researched, and sketched different ideas and designs for our building. This included finding ways that engineers and others had tacked the same (or similar) challenge. Through our research, we discovered that triangles are strong shapes and should be incorporated into our design and that different forms of bracing should be used to add strength and durability to our building.

Our group used our research to create our first design. This building had a square base with 4 layers. Every second layer would be reinforced with diagonal bracing (as we found it was just as strong as cross bracing, using less materials). We then moved onto the next part of the process, creating a prototype.

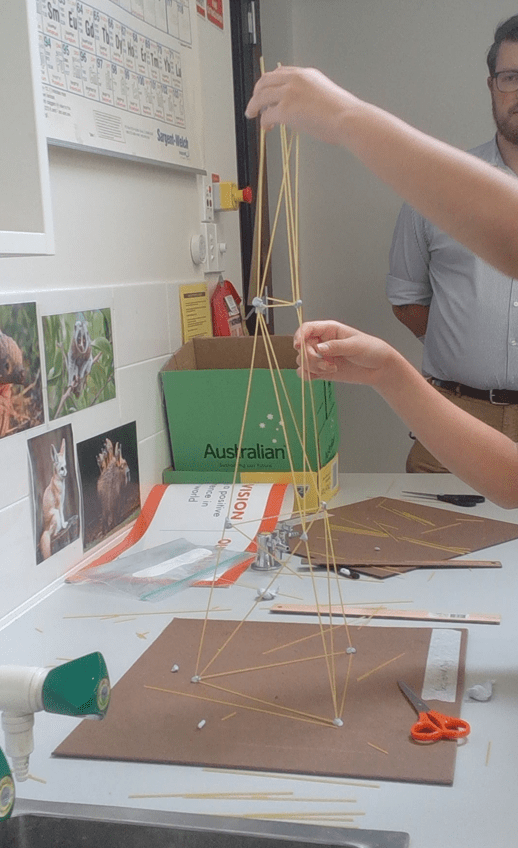

We started out by creating the 25cm x 25cm base and adding the diagonal bracing. When creating the bottom layer, we found that it was extremely strong and sturdy. As we attempted to construct the other layers, we realised that they were not nearly as stable as the base layer, and even when we attempted to add bracing as well (resultantly going over budget), it was still unsuccessful. This can be seen here –>

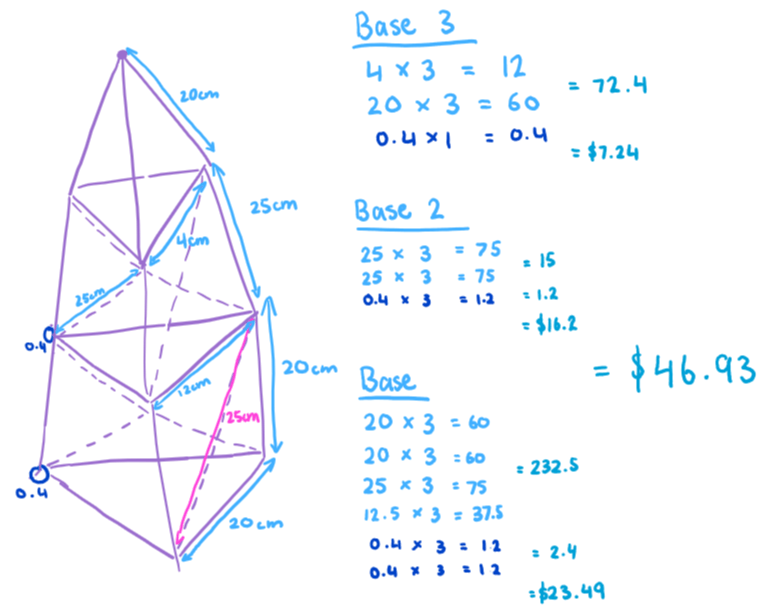

Even though our first design wasn’t successful as a whole, we established that the base structure should be used for our coming towers. We went back to stage 1 and started to design a new building. This time, we resorted to a triangle base which greatly decreased the amount of pasta and BluTack needed, consequently reducing the amount of “money” that we need. This design was much simpler however still stable.

When building this new design, we slightly altered it so that the middle layer was made of 6 x 25cm spaghetti that formed triangles in pairs instead of the diagonal bracing. It still provided the necessary support, however varied the design so that the building was more steady.

The next step was to test our prototype on the earthquake simulator. Here’s a video of the test: https://allsaintswaedu-my.sharepoint.com/:v:/g/personal/l24hog_allsaints_wa_edu_au/Ef1fJsz_7WBHrARXTqGv1gkB2Ikn4QWKsgN1-ssxhCsL7w?e=paElxU

As shown in the video, our building didn’t show any visible damage and was able to withstand all of the quakes. When the building shook, the base was very solid and did not move at all. The second layer could be seen absorbing the shock through the pasta’s flexibility and ability to bend. This is much better than the building being rigid, as the pasta would’ve just snapped.

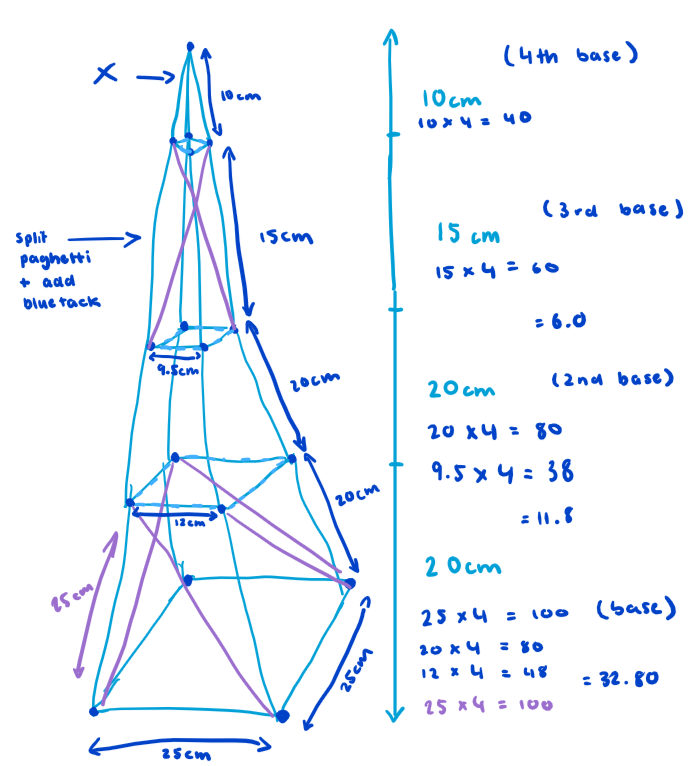

Because our prototype was able to withstand the “earthquake”, our aim for our next “improved” design, was to increase the building’s height, while retaining strength, under the $60 budget. We also wanted to be more accurate with our cutting of the pasta so that our building wouldn’t be lopsided like our first prototype. Our new design had 4 layers to increase the height which is seen in the drafting below.

As we began to build our new design, we kept accidentally snapping the pasta. This led to a very slow start in the construction process as we had to re-measure the pasta and stick it back together. Once we had built the base, we also noticed that the BluTack didn’t seem to be as sticky or solid as before, not securing the pasta together, causing it to be frailer. This meant that when we tried to add the other layers to the base, it didn’t hold together very well and collapsed multiple times. Overall, our new design was not effective in creating an earthquake resistant building which was taller than 60cm, or under the $60 budget as a result of infrastructure breakages.

Because this design failed, we decided to restart and rebuild our old design (the one that resisted the simulated earthquake), but add an extra layer made of 20cm spaghetti and 21cm diagonal braces in attempt to exceed the 60cm height minimum. This caused us to go over budget again. The design was much stronger, however when we added the extra layer, we realised that the base needed to be wider in order for the top to be stable. Resultingly, the building didn’t hold up because of our miscalculations and last-minute planning.

To improve our outcomes, the engineering process could be changed so that we gained feedback from others after we designed our prototypes. This feedback would have made our designs more refined, reducing the number of problems and unsuccessful prototypes we produced in the creating part of the engineering process, therefore helping us to also be more time efficient.

Another change to the engineering process, could be by combining the design and prototype sections. This would help us to understand the strength of the spaghetti, so that we would have a rough idea of how much it can withstand before we design our prototype. In the end, our secondary testing process wasn’t as successful as the first, and our designs weren’t very effective as we weren’t able to create a stable building to be tested again.

At the beginning of this engineering challenge, we all assigned roles to each other. Rebecca was the project manager (keeps the team on track) and reporter (ensures final product is ready by the deadline); Joy was the speaker (seeks help from others); and I was the equipment manager (ensures that all materials are available for the task, and everyone cleans up after). However, as we progressed, we ended up combining the jobs and roles, doing what was needed at the time for our team.

Everyone had their own strengths which allowed our team to succeed to the best of our abilities:

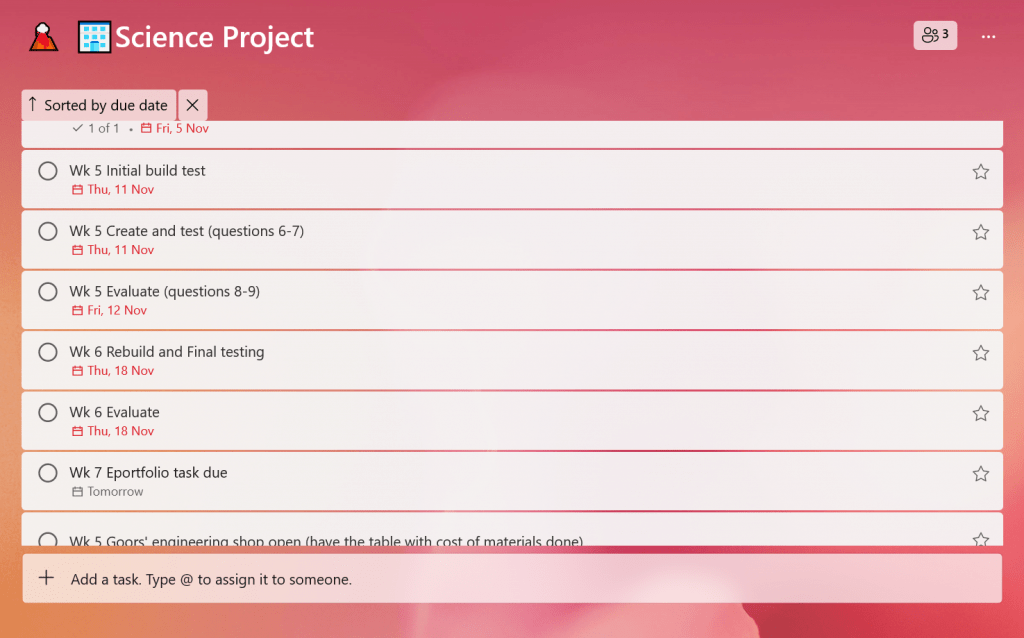

One of my main strengths is organisation. I made sure that our team always knew what we wanted to accomplish in every lesson, and we created a Microsoft To-Do list which had all of the due dates and tasks we had to complete. This helped us to stay on track and submit the various parts of the assessment by the deadlines. Another of my strengths in this project, was creativity. I used my research to back up and influence my decisions and ideas of designs which I proposed to the rest of the group. These ideas turned into our prototypes.

Joy’s strength is effectively communicating with others. She contributed this strength through seeking help from others and explaining our design choices to the teacher and our peers. While Rebecca and I were constructing our tower, Joy would note down the measurements and sketch our final design. This would help calculating the cost and measurements of our tower.

Similar to Joy, Rebecca is very skilled in drawing and sketching detailed design plans. She would draw our design ideas in detail with accurate measurements and estimated heights as a plan that we used while constructing our buildings. Another of Rebecca’s strengths was being inquisitive and creative. She proposed ways to constantly improve our designs.

Altogether, we were always on track and collaborated really well with each other. We all also showed resilience when our designs didn’t go to plan and used our problem-solving skills to alter the prototype. This resulted in our group succeeding while also having fun and accumulating new skills during this engineering challenge.