With this project, we were tasked with creating a building out of spaghetti and blu-tack, that could resist simulated earthquakes on a shake table. Our buildings had to be; 60 cm tall, a maximum of 30×30 base, and inside a budget. The resources we had access to had a cost to use. 10cm of spaghetti was $1 and 1 gram of Blu-tack was $1. We then had to design and build a structure that fit within a $60 budget.

The engineering process we took with this project was simple. We decided to do a rough sketch and design and a little research, then jump straight into the building, changing our design along the way when we encountered any issue

s. Although this process seems crude and rather basic, it actually worked well for our group, as most of us are hands-on visual learners who would prefer to have the raw materials in our hands and start building and creating as soon as possible.

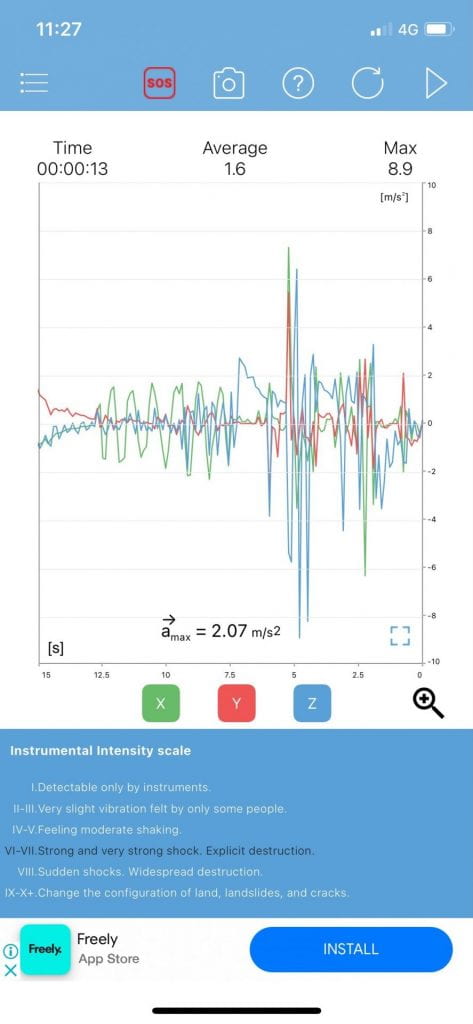

This engineering process did work, and we ended up with a good design that withstood the first round of the shake table. The second time, we simply added more supports and removed some base pieces that were not providing extra support. This change made it a lot stronger, and it withstood the up and down shaking more.

Next time we do this, I would spend more time researching and designing the building we are going to make, as our final design looked nothing like the plan we had made. I think that a little more research and more in-depth planning and designs would make the production process easier, as we would not have to worry about budgets and resources. If we took more time when building as well, we would have broken fewer resources and made a more stable and solid design

When tackling this challenge as a group, each individual provided a different essential skill-set that influenced the design we produced. One team member was very creative and thought outside of the box. This team member really helped during the building process to come up with new ways to attach the spaghetti and different ways to make the base. This team member was essentially the main manager of the actual building process and provided support for all others. Another team member was less suited to the building, but more to keeping everyone on task and staying organised. This team member helped to delegate the tasks at hand and made sure that everyone had a job to do. This team member was happy to step back and advise rather than jump into the rush of building a spaghetti tower.

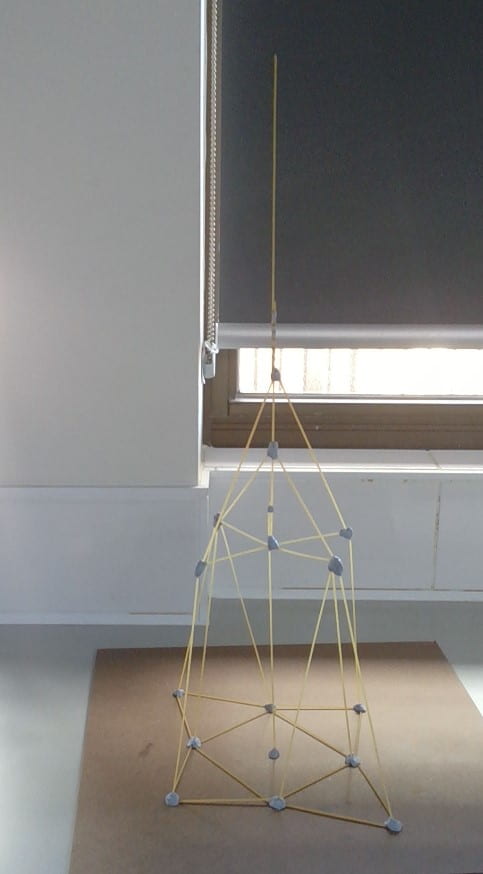

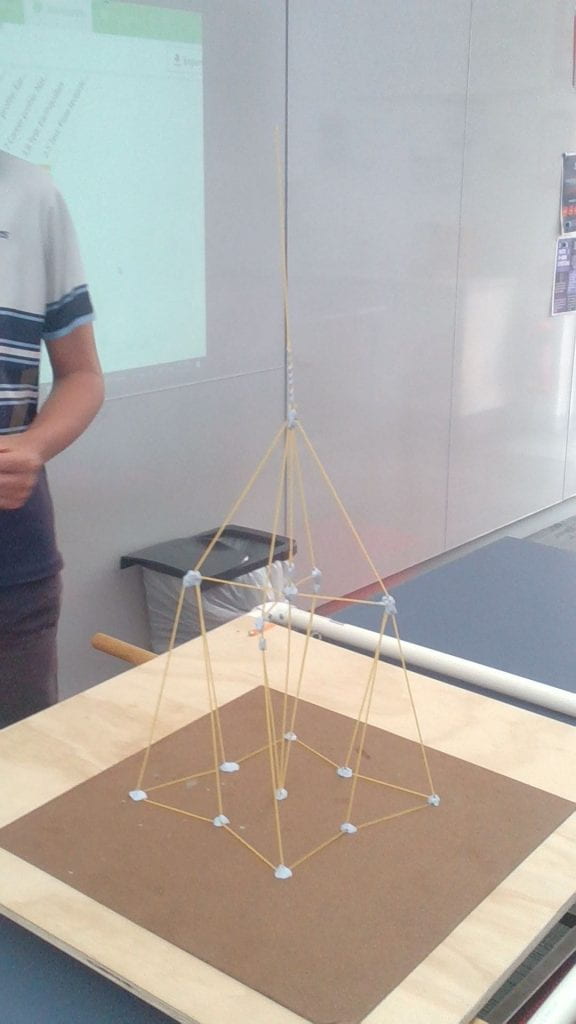

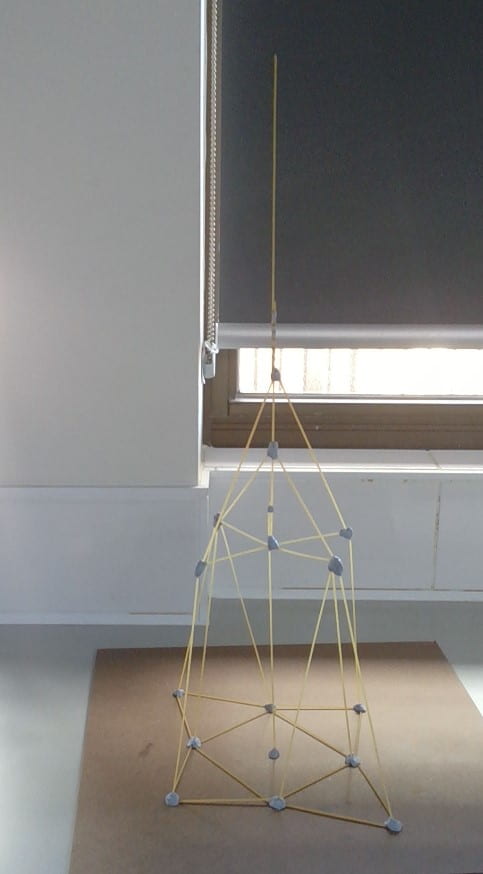

On the left is our original design. And on the right is our first build.

As you can see, our building is very different from our first design. This is because when we visualised the amounts of spaghetti and pasta we could afford, we saw that we would not have enough for all the joints required to build the original design. We then decided to make it up as we went, which actually worked especially well, as we knew how much of each material we could afford.