The aim of this entire project was to design a building that would be able to withstand an earthquake, in groups we would need to design, build and test a scaled model that meets the requirements. The building must have a minimum height of 60cm, have a maximum base of 30cm x 30cm, cost less than $60 to build and remain standing at over 60cm after the simulated earthquake test.

We were challenged to construct an earthquake-resistant building using the materials, spaghetti, blu-tack and our craft skills. By being given the mere budget of $60 to build with all the materials priced, our focus was to build this design so during the simulated earthquake it didn’t crack or break. Our group pitched in our different, individual skills to create this building and reach our focus.

The Engineering Process

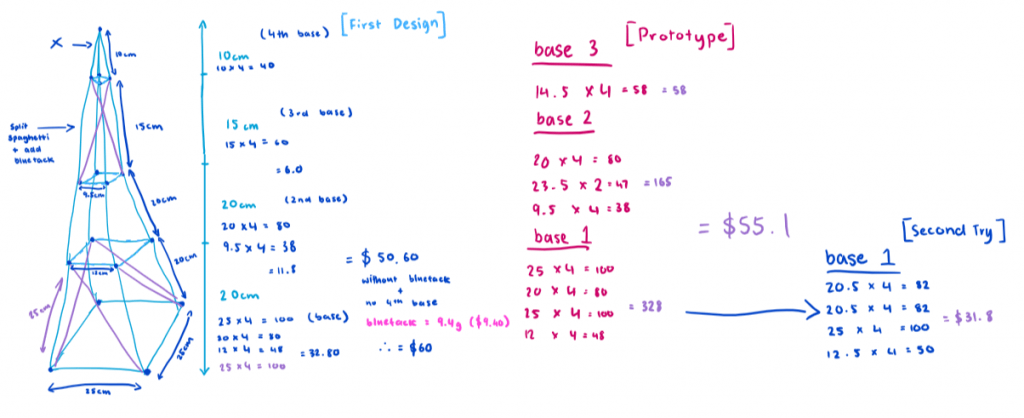

Our group started on brainstorming and researching designs and patterns that could make the building stronger, such as triangles and different building shapes such as the Eiffel Tower. Our first design was constructed with a square base 25cm x 25cm, with 3-4 layers depending on the height after, getting smaller and smaller. When constructing this we put a lot of our focus into the base of the building so that we had a strong foundation to build on top of.

During this process, after trying out our first design, we trialled ways into having the same design but using fewer materials to make it cheaper. Our group kept trying to make the base smaller and smaller, but it ended up not helping as much. This design ended up being way over the $60 budget allowed and it wasn’t as strong as we hoped for, it continuously broke when we tried to build and the spaghetti sticks kept unsticking from the blu-tack. The results of this design were not what we hoped for. After the second week, we decided we wouldn’t be going with this design because of the small budget, us not meeting the height requirement and the strength of our building.

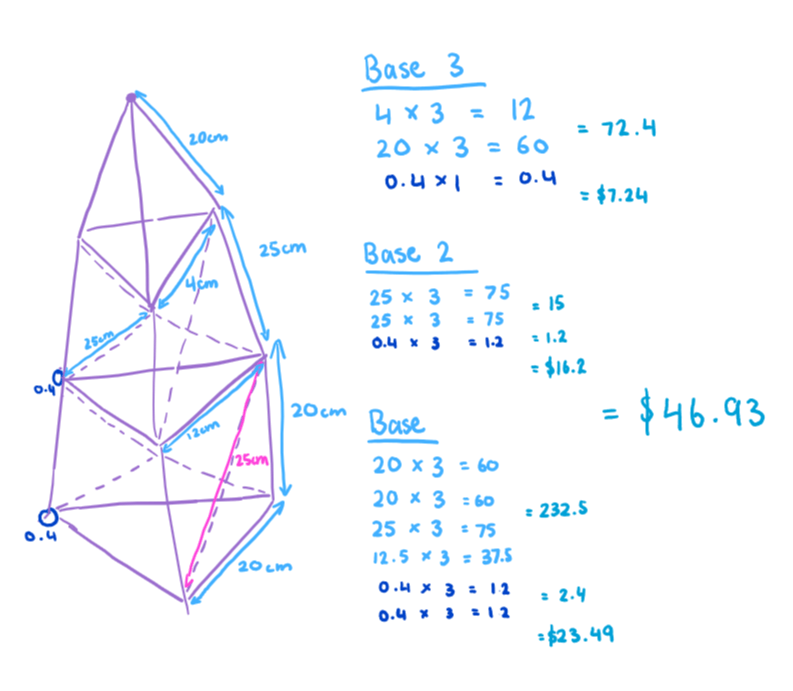

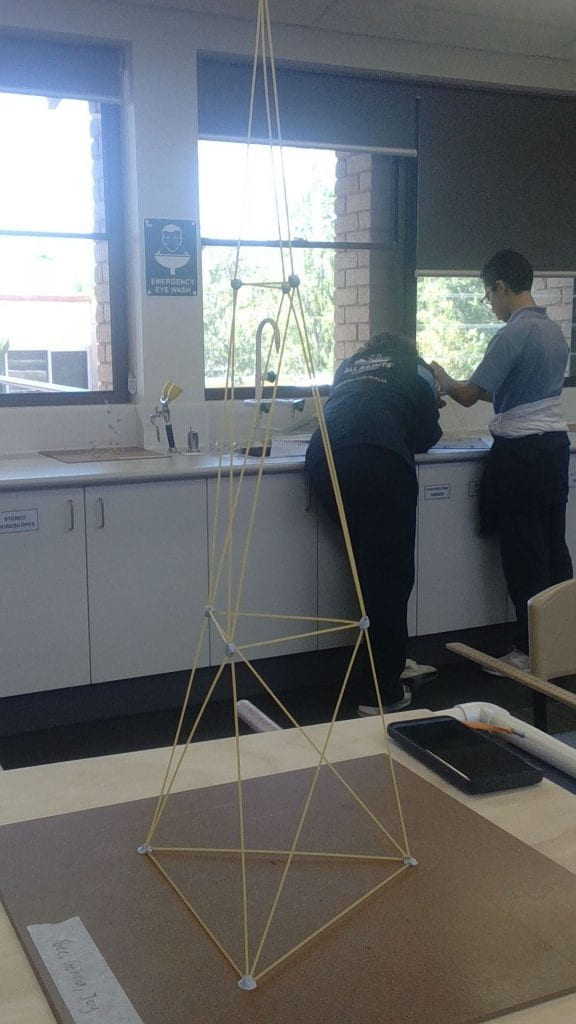

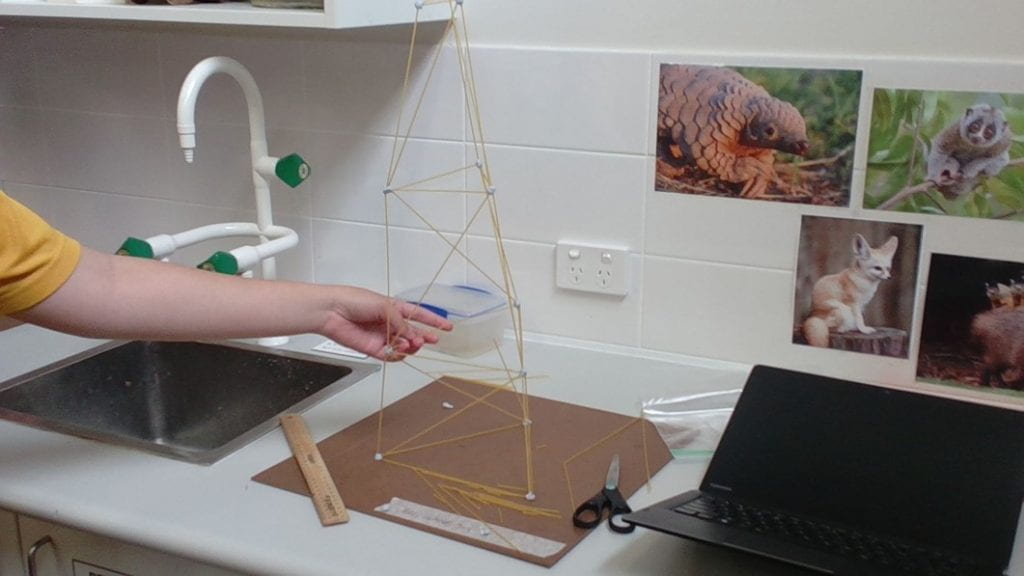

Our group then created a second design to save money to use on blu-tack. Though instead of using a square base like before, we decided to use a triangular base. This design was drawn very quickly and on the same day as we built it, so there was a lot of improvements that could be made to it. The diagonal bracing on the sides of the build makes it stronger to withstand more pressure from the makeshift earthquake so that the spaghetti is not too fragile to snap or topple over. After building this we found out that it was on an angle so next time we have to make sure to measure all the spaghetti sticks well and keep the diagonal bracing because it was very good.

This design was the one to undergo the testing for the simulated earthquake. From the video link below, you can see that the second and third layers wobbled a lot and were quite fragile, but they absorbed lots of energy with no breakages. This was what we had to change for our final design to make the second and third layers stronger. To pass this test, the building must remain over 60cm before and after the earthquake and there shouldn’t be any cracks or breakages in the building. Our building passed the simulated earthquake test remaining the same height at 64.5cm. Now our challenge is to either build a spaghetti building using fewer materials or make it taller to withstand the same test.

Link to building surviving earthquake video here —>https://allsaintswaedu-my.sharepoint.com/:v:/g/personal/l24hog_allsaints_wa_edu_au/Ef1fJsz_7WBHrARXTqGv1gkB2Ikn4QWKsgN1-ssxhCsL7w?e=paElxU

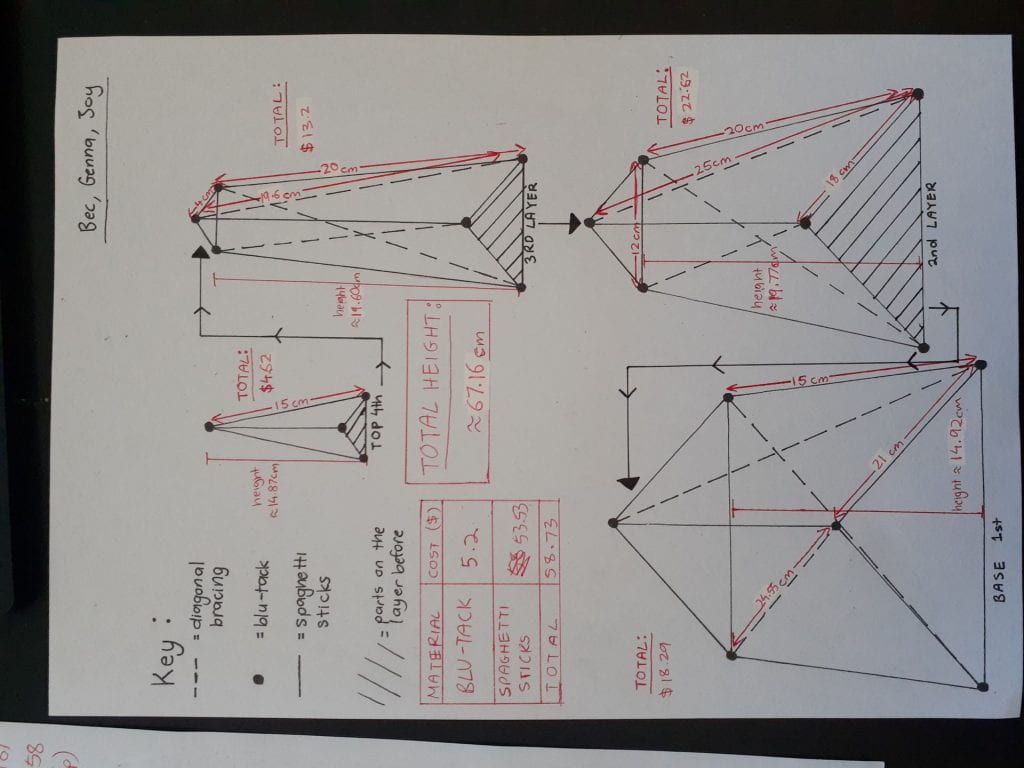

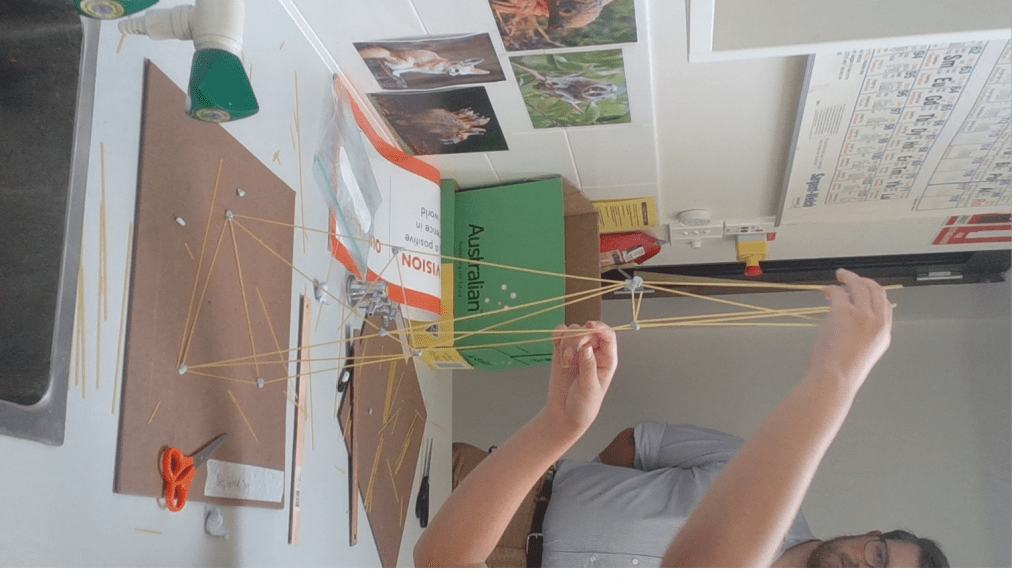

Finally, we reached the last week of this project to build and create our final design. As a group we decided to make a 4th layer to our second design which passed the test, making the building taller and accurately measuring spaghetti so that the building doesn’t end up tilted. The new design changes we made to the building didn’t work out well and continuously collapsed down which hindered the rest of the structure. While building we also figured out that it would go over budget and even when trying our best to measure accurately, the building still ended up, tilted. Our blu-tack didn’t stick well, which made it very frustrating to continue as the spaghetti would unstick every couple of minutes.

This design ended up as a fail but to try to build something we stuck with our 2nd design which succeeded and restarted, completely changing our design to imitate the second one in our last 30 minutes of class. But in the end, this didn’t work as well and none of the blu-tack stuck to the spaghetti.

Changes to the engineering process

Changes to the engineering process that would improve the outcome would be to instead of only keep ideas and feedback as a group or asking questions and feedback from teachers, is to include using our peers. After creating a design, we could ask for peer feedback on the building and have them give us constructive feedback vice versa. This would be a great way to improve the outcomes of our building passing the simulated earthquake test. If we were to get peer feedback, it would give us opinions and ideas from different perspectives and not from the designers. When creating and developing a design we could ask for peer feedback so that we wouldn’t have as many prototypes as we do now (4 different designs) that take up a lot of time and effort to create and build then re-design.

Another change that we could make to our engineering process would be job distribution. Even though we have roles in our small groups, it didn’t work out that well. The original roles of our group were that Bec was the reporter and equipment manager, Genna was the equipment manager, and I was the speaker. The reporter’s role is to make sure that the final presentation is ready by the deadline. The project managers role is to make sure that everyone understands the challenge and keeps the team on track. The equipment manager makes sure that the materials needed for the task are available and everyone cleans up after each session and the speaker’s role is to seek help from the teacher, other class members or outside experts. Instead of something like this, we could have roles such as the main building designer, or the person who measures, cuts and weights the spaghetti and blu-tack, and a builder to build the structure. This would be a good way to create a better outcome for the engineering process, so that everybody has a role and something to do in the project, creating more participation. Leading to more ideas and less failure.

Teamwork

Each member of our group contributed to the team differently. All our strengths worked well together to complete this engineering project. During the time researching, designing, building and improving on the design constantly, we all used a range of strengths to work through the ups and downs. Our group has many different strengths which contributed to this project below.

Genna – She contributed to the team by her research, looking into different structures, buildings and patterns that are the strongest to withstand a makeshift earthquake, which we could incorporate into our building. She proposed many ideas to the group, on ways to make the base stronger and the building taller without using too many materials. Genna kept the group organised and on task throughout the project so that we wouldn’t miss deadlines and mostly helped in constructing our building.

Bec – She contributed many ideas to the group on ways to alter the design in different ways. Rebecca made detailed sketches and drawings of the final design for our group to use, which included the challenge we were tasked with. She also added up measurements together, and she would accurately cut materials and weight blu-tack so we would have each side of our building equal whilst also helping to construct our building.

Me (Joy) – I contributed to the team by bringing ideas on what I thought would work or not work, improvements to be made and communicated with others, asking for feedback from teachers and communicating with our team, to see what we liked and disliked about our design. Whilst mainly Genna and Bec built, I sketched as we went because we failed so many times we decided to just try building. So when they built I sketched the design down and made sure to take notes on the measurements of each side, the diagonal bracing and added up all the measurements and blu-tack together to see if we were under or over budget.

Everybody in our group had good focus on the task that was placed in front of us and we were always on track with what we were doing. We made sure to be done on time by all the deadlines and materials were always available to us for building. If anything went wrong with the building, designing or calculations we would always rationally do things and figure out the problem using our strength and expertise. Sometimes we succeeded with our buildings and sometimes we failed with them, it was all part of the process.